| RESEARCH PAPER |

|

|

|

|

|

|

| Effect of Solution Treatment on the Microstructure and Mechanical Properties of GH3625 Superalloy Sheet |

| Yutian DING,Bin MENG,Yubi GAO,Xin GAO,Zhengyi DOU,Yuanjun MA

|

| State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals, Lanzhou University of Technology, Lanzhou 730050 |

|

|

|

|

Abstract The influence of solution treatment on microstructure and mechanical properties of GH3625 alloy sheet were investigated by OM, SEM, EDS, universal testing machine and Rockwell hardness tester and other means. The results indicated that the grains were equiaxed and there were a large number of annealing twins after the solution treatment. As solution treatment temperature was more than 1 130 ℃, the carbides in alloy almost completely dissolve into the matrix. Grain size was prompted by temperature increasing in the range of 890 ℃ to 1 190 ℃, and the energy (Qg) of grain growth was 227.18 kJ/mol. At different solution temperature, the grain size and room-temperature mechanical properties of GH3625 alloy accord with Hall-Petch relation. The main strengthening mechanism was fine grained strengthening. With the increase of temperature, the fracture mode of GH3625 alloy sheet was changed from brittle fracture to ductile fracture.

|

|

Published: 25 January 2018

Online: 2018-01-25

|

|

|

|

|

| C | Si | Mn | P | S | Cr | Fe | Mo | V | Cu | Ni | | 0.047 2 | 0.283 | 0.203 | <0.000 3 | 0.001 65 | 21.36 | 0.605 | 9.12 | 0.025 7 | 0.014 8 | 64.1 | | W | Co | Nb | Al | Ti | Zr | Sn | B | Mg | Ta | | | 0.000 96 | 0.018 8 | 3.74 | 0.213 | 0.246 | 0.002 55 | 0.003 65 | <0.000 1 | 0.002 89 | 0.028 8 | |

|

|

Chemical composition (mass fraction/%) of experimental material

|

|

|

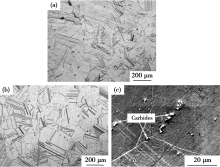

Original microstructure of GH3625 alloy

|

|

|

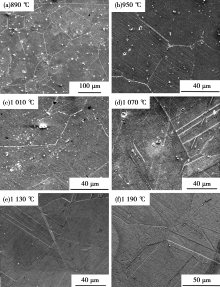

Microstructure of GH3625 alloy treated at different temperatures

|

|

|

Distribution of precipitated phase of GH3625 alloy at different solution temperatures

|

|

|

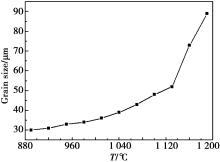

Effect of solution treatment temperature on grain size

|

|

|

Relationship between grain size and solution treatment temperature for GH3625 alloy

|

|

|

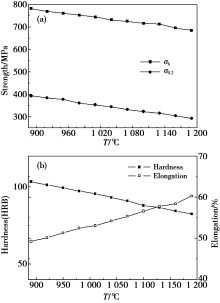

Effect of solution treatment temperature on mechanical property

|

|

|

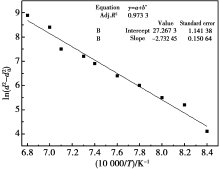

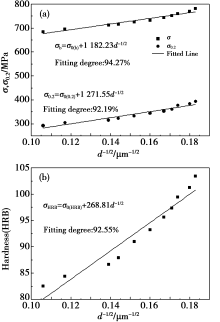

Hall-Petch relation of GH3625 alloy after solution treatment at different temperature

|

|

|

Original fracture morphology of GH3625 alloy sheet

|

|

|

Fracture morphology of GH3625 alloy after solution treatment at different temperature

|

| 1 | 1 冶军 . 美国镍基高温合金[M]. 北京: 科学出版社, 1978: 228. | | 2 | 2 黄乾尧, 李汉康, 陈国良 , 等. 高温合金[M]. 北京:冶金工业出社, 2000: 31. | | 3 | 3 Zhang H B. Inconel625 alloy progress abroad[J].Special Steel Technology, 2000(3):69(in Chinese). | | 4 | 张红斌 . 国外Inconel625合金的进展[J].特钢技术, 2000(3):69. | | 5 | 4 郭建亭. 高温合金材料学[M]. 北京: 科学出版社, 2008: 87. | | 6 | Shankar V, Rao K B S, Mannan S L . Microstructure and mechanical properties of Inconel 625 superalloy[J]. Journal of Nuclear Mate-rials, 2001,288(2-3):222. | | 7 | Floreen S, Fuchs G E, Yang W J . “The metallurgy of alloy 625” superalloys 718, 625 and various derivatives[M]. TMS,Warrendale,PA, 1994: 13. | | 8 | Ou X Z, Yao L, Huang Y P . Influence of solution temperature on the microstructure and mechanical properties of UNS N06625 alloy[J]. Metallic Functional Materials, 2016,23(2):55(in Chinese). | | 9 | 欧新哲, 姚雷, 黄妍凭 . 固溶处理对UNS N06625合金组织和力学性能的影响[J]. 金属功能材料, 2016,23(2):55. | | 10 | Peng C H, Chang H, Hu R , et al. Static recrystallization kinetics of Haynes230 superalloy[J]. Journal of Aeronautical Materials, 2011,31(2):8(in Chinese). | | 11 | 彭聪辉, 常辉, 胡锐 , 等. Haynes230高温合金的静态再结晶动力学[J]. 航空材料学报, 2011,31(2):8. | | 12 | 9 余永宁. 位错理论[M]. 北京: 北京钢铁学院出版社, 1984: 24. | | 13 | Yang G, Sun L J, Zhang L N , et al. Annihilation of deformation twins and formation of annealing twins[J]. Journal of Iron and Steel Research, 2009,21(2):39(in Chinese). | | 14 | 杨钢, 孙利军, 张丽娜 , 等. 形变孪晶的消失与退火孪晶的形成机制[J]. 钢铁研究学报, 2009,21(2):39. | | 15 | 11 董建新. 镍基合金管材挤压及组织控制[M]. 北京: 冶金工业出版社, 2014. | | 16 | Yang G, Wang C, Zhang L Y , et al. Recovery and recrystallization mechanism in austenitic stainless steel[J]. Transactions of Materials and Heat Treatment, 2010,31(12):51(in Chinese). | | 17 | 杨钢, 王昌, 张凌义 , 等. 奥氏体不锈钢的回复与再结晶机制[J]. 材料热处理学报, 2010,31(12):51. | | 18 | Xia S, Li H, Zhou B X , et al. Control and application of annealing twins in metallic materials: Grain boundary engineering[J]. Chinese Journal of Nature, 2010,32(2):94(in Chinese). | | 19 | 夏爽, 李慧, 周邦新 , 等. 金属材料中退火孪晶的控制及利用——晶界工程研究[J]. 自然杂志, 2010,32(2):94. | | 20 | 14 董建新. 高温合金GH4738及应用[M]. 北京: 冶金工业出版社, 2014: 16. | | 21 | Feng H, Song Z G, Zheng W J , et al. Effect of solution treatment on microstructure and mechanical property of Inconel690[J]. Journal of Iron and Steel Research, 2009,21(3):46(in Chinese). | | 22 | 丰涵, 宋志刚, 郑文杰 , 等. 固溶处理对Inconel690合金组织和力学性能的影响[J]. 钢铁研究学报, 2009,21(3):46. | | 23 | Kai J J, Yu G P, Tsai C H , et al. The effects of heat treatment on the chromium depletion, precipitate evolution and corrosion resis-tance of lnconel alloy 690[J]. Metallurgical Transactions A, 1989,20:2057. | | 24 | 17 毛卫民. 金属的再结晶与晶粒长大[M]. 北京: 冶金工业出版社, 1994: 62. | | 25 | Fang X D, Han D P, Li Y . Effect of heat treatment on microstructure and mechanical properties of GH625 alloy[J]. Hot Working Technology, 2013,42(8):204(in Chinses). | | 26 | 方旭东, 韩德培, 李阳 . 热处理对GH625合金热挤压管材组织及力学性能的影响[J]. 热加工工艺, 2013,42(8):204. | | 27 | Sellars S M, Whiteman J A . Recrystallization and grain growth in hot rolling[J]. Metal Science, 1979,13:198. | | 28 | Anelli E . Application of mathematical modelling to hot rolling and controlled colling of wire rods and bars[J]. ISIJ Interational, 1992,32:440. | | 29 | Guo Q M, Li H T, Li D F , et al. Hot extrusion moulding process and microstructure evolution of GH625 superalloy tubes[J]. Chinese Journal of Rare Metals, 2011,35(5):684(in Chinese). | | 30 | 郭青苗, 李海涛, 李德富 , 等. GH625合金管材热挤压成形工艺及组织演变的研究[J]. 稀有金属, 2011,35(5):684. | | 31 | 22 杨德庄. 位错与金属强化机制[M]. 哈尔滨: 哈尔滨工业大学出版社, 1991. | | 32 | Zhong Q P, Zhao Z H, Zhang Z . Development of “Fractography” and research of fracture micromechanism[J]. Journal of Mechanical Strength, 2005,27(3):358(in Chinese). | | 33 | 钟群鹏, 赵子华, 张峥 . 断口学的发展及微观断裂机理研究[J]. 机械强度, 2005,27(3):358. | | 34 | 4 Wu D, Tian L X, Ma C L , et al. Tensile fracture behavior of Ni-based single crystal superalloy[J]. Materials Review B:Research Papers, 2016,30(12):76(in Chinese). | | 35 | 武丹, 田礼熙, 马朝利 , 等. 镍基单晶高温合金的拉伸断裂行为[J]. 材料导报:研究篇, 2016,30(12):76. |

|

| [1] |

LIU Yuanhao, REN Changjing, XIANG Yanjun, YUE Shiqi, NI Yu, ZHANG Pengxian, HUANG Yong, HUANG Jiankang. Influence of Activator on the Penetration Depth, Arc Morphology, Microstructure and Properties of A-TIG Joints[J]. Materials Reports, 2025, 39(1): 23120053-5. |

|

|

|

|

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

2018, Vol. 32

2018, Vol. 32