| RESEARCH PAPER |

|

|

|

|

|

|

| Study on UV Curing Behavior and Properties of ES/CEP Resin |

| Zhouhui YU,Peizhong ZHAO,Fangyou HU

|

| Department of Aeronautical and Mechanical Engineering, Qingdao Branch, Naval Academy of Aeronautical Engineering, Qingdao 266041 |

|

|

|

|

Abstract The effect of process parameters, including epoxy resin composition, curing time, initiator types and levels on curing behavior were studied by taking organic silicone as toughening agent to modified epoxy resin. Curing product was analyzed by TG and DSC. The results showed that when the content of initiator 820 and T were 2%, the ratio of epoxy resin and silicone resin was 85∶15, resin system could achieve good solidification effect under the high pressure mercury lamp with 15 minutes UV curing. The tensile strength of blending resin with 15% organic silicon resin slight declines while toughness improved obviously compared with pure epoxy resin. At the same time, glass transition temperature decreased 7.5 ℃ and thermal degradation rate significantly decreased in rapid floating zone.

|

|

Published: 25 January 2018

Online: 2018-01-25

|

|

|

|

|

| Model | Appearance | Dynamic

viscosity

cP | Epoxide

number

mol/100 g | | UVR-6128 | Light yellow

thickened and

transparent liquid | 400—750 | 0.45—0.53 | | ES06 | Yellow

transparent | 115—300 | 0.03—0.08 |

|

|

The main properties of the resin

|

| Sample | CEP | ES | 820 | T | | S1 | 100 | 0 | 0 | 2 | | S2 | 100 | 0 | 1 | 2 | | S3 | 100 | 0 | 2 | 2 | | S4 | 100 | 0 | 3 | 2 | | S5 | 100 | 0 | 4 | 2 | | S6 | 100 | 0 | 2 | 0 | | S7 | 100 | 0 | 2 | 1 | | S8 | 100 | 0 | 2 | 3 | | S9 | 100 | 0 | 2 | 4 | | S10 | 90 | 10 | 2 | 2 | | S11 | 85 | 15 | 2 | 2 | | S12 | 80 | 20 | 2 | 2 | | S13 | 75 | 25 | 2 | 2 | | S14 | 70 | 30 | 2 | 2 |

|

|

|

|

|

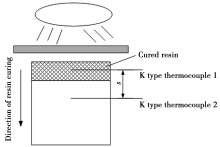

Schematic of resin curing

|

|

|

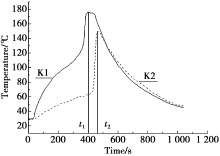

Typical temperature change curve of different ratio of resin

|

|

|

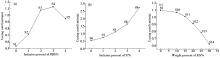

The effects of different ratio of resin on curing rate

|

|

|

Gel conversion rate of different ratio of resin with different light time

|

|

|

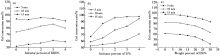

The influence of mass fraction of ES on the mechanical behavior of ES/CEP blend

|

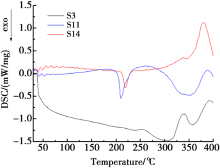

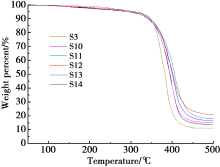

| Sample | S3 | S10 | S11 | S12 | S13 | S14 | | Tg/℃ | 230.1 | 224.8 | 222.6 | 217.5 | 211.7 | 210.2 | | Td,5%/℃ | 310.6 | 309.4 | 312.1 | 308.3 | 302.4 | 296.5 |

|

|

Thermal properties of ES/CEP resin

|

|

|

DSC curve of ES/CEP resin

|

|

|

TG curve of ES/CEP resin

|

| 1 | 1 Wang Z G, Liu W S, Zhao L N. Progress on molecular design and synjournal of high-performance cycloaliphatic epoxy resins[J].Chinese Polymer Bulletin, 2011(9):13(in Chinese). | | 2 | 王忠刚, 刘万双, 赵琳妮 . 高性能脂环族环氧树脂分子设计与合成研究进展[J].高分子通报, 2011(9):13. | | 3 | He Yong, Xiao Ming, Wu Feipeng . Photopolymerization kinetics of cycloaliphatic epoxide-acrylate hybrid monomer[J]. Polymer International, 2007,56(10):1297. | | 4 | Bulut U, Crivello J V . Investigation of the reactivity of epoxide monomers in photoinitiated cationtic polymerization[J]. Macromolecules, 2005,38:3584. | | 5 | Wu C F, Chen W J, Lin C H , et al. Morphology and properties of rubber elastomer toughened epoxy resins[J]. Thermosetting Resin, 2014,29(3):40(in Chinese). | | 6 | 吴传芬, 陈文静, 林长红 , 等. 橡胶弹性体增韧环氧树脂的结构与性能研究[J]. 热固性树脂, 2014,29(3):40. | | 7 | Shi X X, Yuan C K, Wang C P , et al. Progress of organic silicone modified epoxy resin[J]. Chinese Polymer Bulletin, 2015,25(4):18(in Chinese). | | 8 | 石新秀, 袁崇凯, 王传萍 , 等. 有机硅改性环氧树脂的新进展[J]. 高分子通报, 2015,25(4):18. | | 9 | Jiang J Q, Liu J C, Zhang S W , et al. Progress in the research of toughening epoxy resin and mechanism[J]. Journal of Jiangnan University, 2009,8(5):625(in Chinese). | | 10 | 江金强, 刘敬成, 张胜文 , 等. 环氧树脂增韧改性方法及机理研究进展[J]. 江南大学学报, 2009,8(5):625. | | 11 | Xu K . Preparation and properties of UV-curable poly(urethane-acrylate)/ZrO2 nanocomposite coatings[D]. Shanghai:Fudan University, 2009(in Chinese). | | 12 | 徐坤 . 紫外光固化聚氨酯丙烯酸酯/ZrO2纳米复合涂层的制备和性能研究[D]. 上海:复旦大学, 2009. | | 13 | Wei Z J, Liu W Q, Li H J . Properties of phosphorous-containg organic silicone/epoxy hybrid resin[J]. Acta Polymerica Sinica, 2012,2(2):148(in Chinese). | | 14 | 魏振杰, 刘伟区, 李宏静 . 含磷有机硅杂化环氧树脂固化体系性能研究[J]. 高分子学报, 2012,2(2):148. | | 15 | Chang J, Li M Y, Hong Y Q , et al. Toughness and solid residue of epoxy resins modified by merhyl silicone oligomer[J]. Polymer Material Science and Engineering, 2013,29(8):72(in Chinese). | | 16 | 常金, 李茂源, 洪义强 , 等. 甲基苯基有机硅低聚物改性环氧树脂的韧性及热残重[J]. 高分子材料科学与工程, 2013,29(8):72. | | 17 | Sarah Sobhani, Ali Jannesari, Saeed Bastani . Effect of molecular weight and content of PDMS on morphology and properties of silicone-modified epoxy resin[J]. Applied Polymer Science, 2012,123(1):162. | | 18 | Yang G, Huang P C . UV treatment of blended epoxy resin and its surface chemical reaction[J]. Journal of Beijing University of Aeronautics and Astronautics, 2008,34(6):618(in Chinese). | | 19 | 杨光, 黄鹏程 . 环氧共混树脂的光固化及其表面化学反应[J]. 北京航空航天学报, 2008,34(6):618. | | 20 | Li C, Qi Y C, Zhang Y Q , et al. Preparation and properties of UV curable cycloalipatic epoxy acrylate coatings[J]. Journal of Function Polymers, 2012,1(3):62(in Chinese). | | 21 | 黎朝, 祈元春, 张彦庆 , 等. 紫外光固化脂环族环氧丙烯酸酯涂料的制备及性能[J]. 功能高分子学报, 2012,1(3):62. | | 22 | 13 金养智. 光固化材料性能及应用手册[M]. 北京: 化学工业出版社, 2010. | | 23 | Studer K, Decker C, Beck E , et al. Thermal and photochemical curing of isocyanate and acrylate functionalized oligomers[J]. Euro-pean Polymer Journal, 2005,41(1):157. | | 24 | Zhao Peizhong, Hu Fangyou, Huang Xuren . Preparation and cha-racterization of structurally graded poly(urethane-urea) elastomers[J]. Polymer-Plastics Technology and Engineering, 2012,51(7):663. | | 25 | Kumar S A, Narayanan T S . Thermal properties of siliconized epoxy interpenetrating coastings[J]. Progress in Organic Coatings, 2002,45(4):323. |

|

|

|

|

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

2018, Vol. 32

2018, Vol. 32