| RESEARCH PAPER |

|

|

|

|

|

|

| Mechanism Study of High-temperature Deformation of Oxide Scale on Hot-rolled Steel |

| Zhifeng LI1,Yongquan HE2,Guangming CAO1,Junjian TANG1,Zhenyu LIU1

|

1 The State Key Laboratory of Rolling and Automation, Northeastern University, Shenyang 110819

2 The School of Mechatronics Engineering, Zhengzhou University of Aeronautics, Zhengzhou 450015 |

|

|

|

|

Abstract The high-temperature deformation mechanism of oxide scale on low micro-alloy carbon steel was studied using a thermo-mechanical simulator. The thickness, cross-sectional morphology, element distribution and grain structure of oxide scale were observed by electron probe microanalysis (EPMA) and electron backscatter diffraction (EBSD). The results indicated that the plasticity of oxide scale depended on temperature and degree of deformation. Furthermore, FeO layer was the primary region where plastic deformation distributed. This can be explained by the grain structure of FeO layer consisted of loose and larger columnar grains which was beneficial to the plastic deformation. Therefore, the oxide scale and steel substrate at high-temperature developed in equal proportion according to the plastic deformation mechanism of oxide scale, which revealed that the surface quality of hot-rolled steel could be improved by the hot-rolled process.

|

|

Published: 25 January 2018

Online: 2018-01-25

|

|

|

|

|

|

|

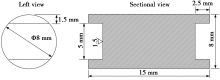

The left view and sectional view of specimen

|

|

|

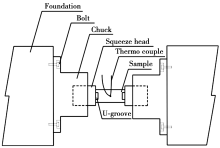

Schematic of simulating the high-temperature deformation behavior of oxide scale

|

|

|

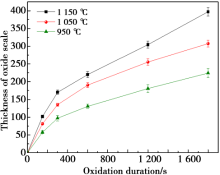

Oxidation kinetics of specimens at high-temperature

|

|

|

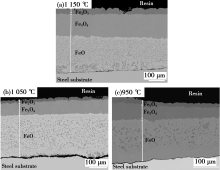

Cross-section morphology of specimens’ oxide scale for 1 800 s at high-temperature

|

|

|

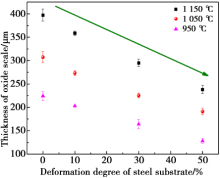

Changes in thickness of oxide scale as a function of deformation

|

|

|

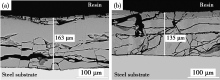

The cross-section morphology of specimens’ oxide scale after deformation:(a)reduction 30% at 950 ℃, (b)reduction 50% at 950 ℃

|

|

|

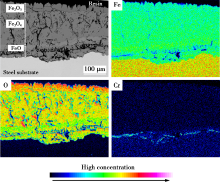

The cross-section morphology and element distribution of specimen’s oxide scale after reduction 50% at 1 150 ℃

|

|

|

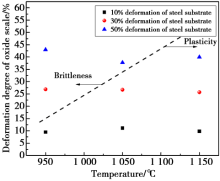

Plastic behavior of the oxide scale as a function of reduction and temperature

|

|

|

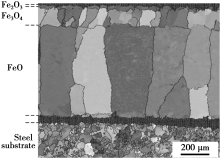

Cross-sectional structure of oxide scale of specimen after 10 min oxidation at 1 050 ℃

|

| 1 | Genève D, Rouxel D, Pigeat P , et al. Descaling ability of low-alloy steel wires depending on composition and rolling process[J]. Corrosion Science, 2010,52(4):1155. | | 2 | Chattopadhyay A, Kumar P, Roy D . Study on formation of “easy to remove oxide scale” during mechanical descaling of high carbon wire rods[J]. Surface and Coatings Technology, 2009,203(19):2912. | | 3 | Abuluwefa H T, Guthrie R I L, Ajersch F . Oxidation of low carbon steel in multicomponent gases: Part I. Reaction mechanisms during isothermal oxidation[J]. Metallurgical and Materials Transactions A, 1997,28(8):1633. | | 4 | Zhou C H, Ma H T, Wang L . Effect of compressive stresses on microstructure of scales formed on pure iron during continuous air coo-ling[J]. Journal of Iron and Steel Research International, 2010,17(2):27. | | 5 | Hu X J, Zhang B M, Chen S H , et al. Oxide scale growth on high carbon steel at high temperatures[J]. Journal of Iron and Steel Research International, 2013,20(1):47. | | 6 | Yu X, Jiang Z, Zhao J , et al. Effects of grain boundaries in oxide scale on tribological properties of nanoparticles lubrication[J]. Wear, 2015,333:1286. | | 7 | West G D, Birosca S, Higginson R L . Phase determination and microstructure of oxide scales formed on steel at high temperature[J]. Journal of Microscopy, 2005,217(2):122. | | 8 | Wei D B, Huang J X, Zhang A W , et al. The effect of oxide scale of stainless steels on friction and surface roughness in hot rolling[J]. Wear, 2011,271:2417. | | 9 | Jiang Z Y, Tang J, Sun W , et al. Analysis of tribological feature of the oxide scale in hot strip rolling[J]. Tribology International, 2010,43(8):1339. | | 10 | Basabe V V, Szpunar J A . Growth rate and phase composition of oxide scales during hot rolling of low carbon steel[J]. ISIJ International, 2004,44(9):1554. | | 11 | Hidaka Y, Anraku T, Otsuka N . Deformation of iron oxides upon tensile tests at 600-1 250 ℃[J]. Oxidation of Metals, 2003,59(1):97. | | 12 | Kim B K, Szpunar J A . Orientation imaging microscopy for the study on high temperature oxidation[J]. Scripta Materialia, 2001,44(11):2605. | | 13 | Suárez L, Houbaert Y, Eynde X V , et al. High temperature deformation of oxide scale[J]. Corrosion Science, 2009,51(2):309. |

|

|

|

|

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

2018, Vol. 32

2018, Vol. 32