| RESEARCH PAPER |

|

|

|

|

|

|

| Synthesis and Performance of Magnetic Oil Absorption Material with Rice Chaff Support |

| Xu LI1,2,Ziru WANG1,2,Li YANG1,2,Zhendong ZHANG1,2,Youting ZHANG1,2,Yifan DU1,2

|

1 Key Laboratory of Subsurface Hydrology and Ecological Effects in Arid Region of Ministry of Education, Chang’an University, Xi’an 710054;

2 College of Environmental Science and Engineering,Chang’an University, Xi’an 710054; |

|

|

|

|

Abstract A novel magnetic rice chaff oil absorption material was successfully synthesized by immobilizing Fe3O4 nanoparticles onto rice chaff with the aid of mussel-inspired polydopamine and subsequently chemical modification by octadecylamine with low surface energy. Scanning electron microscope (SEM), infrared spectrometer (FTIR) and X-ray diffraction (XRD) instrument were used to characterize the morphology, crystallinity and functional groups of the obtained magnetic rice chaff. The results indicated the magnetic rice chaff had large water contact angle of 135° and magnetic saturation intensity of 39.6 emu/g. The highest oil absorption of magnetic rice chaff reached 6.83 times of its own weight for chloroform. The prepared magnetic rice chaff oil absorption material with high recyclability could be widely used in large-scale removal of spilled oil from water.

|

|

Published: 25 January 2018

Online: 2018-01-25

|

|

|

|

|

|

|

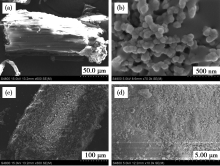

SEM images of the (a) original rice chaff, (b) Fe3O4 nanoparticles and (c, d) magnetic rice chaff oil absorption material

|

|

|

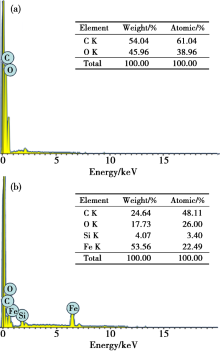

EDS spectra of (a) the original rice chaff and (b) magnetic rice chaff oil absorption material

|

|

|

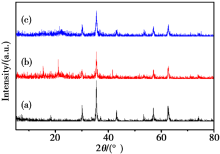

XRD patterns of (a) Fe3O4 nanoparticles, (b) the original rice chaff and (c) magnetic rice chaff oil absorption material

|

|

|

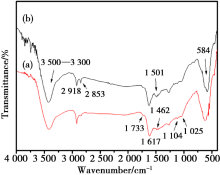

FTIR spectra of (a) the original rice chaff and (b) magnetic rice chaff oil absorption material

|

|

|

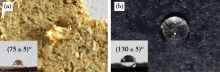

Contact angle of a 2 μL water droplet on the (a) rice chaff and (b) magnetic rice chaff oil absorption material

|

|

|

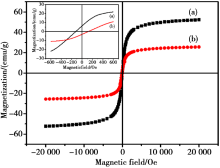

Magnetic hysteresis chart of (a) Fe3O4 nanoparticles and (b) magnetic rice chaff oil absorption material

|

|

|

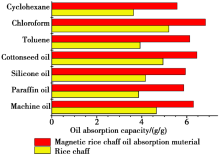

Oil absorption capacity of rice chaff and magnetic rice chaff oil absorption material for different oils

|

|

|

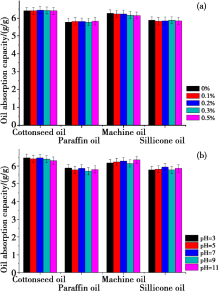

Oil absorption capacity of magnetic rice chaff oil absorption material in (a) different concentration of NaCl and (b) different pH value

|

|

|

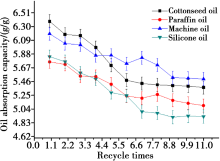

Recyclability of magnetic rice chaff oil absorption material for different oils

|

| 1 | Cojocaru C, Macoveanu M, Cretescu I . Peat-based sorbents for the removal of oil spills from water surface: Application of artificial neural network modeling[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2011,384(1):675. | | 2 | Al-Majed A A , et al. A sustainable approach to controlling oil spills[J]. Journal of Environmental Management, 2012,113:213. | | 3 | McNutt M K, Camilli R, Crone T J , et al. Review of flow rate estimates of the deepwater horizon oil spill[J]. Proceedings of the National Academy of Sciences, 2012,109(50):20260. | | 4 | 4 Radeti c ' M M , Joci c ' D M , Iovanti c ' P M , et al. Recycled wool-based nonwoven material as an oil sorbent[J]. Environmental Science & Technology, 2003,37(5):1008. | | 5 | Wu B, Zhou M H . Sorption of styrene from aqueous solutions with oil absorptive resin[J]. Journal of Environmental Management, 2009,90(1):217. | | 6 | Okiel K, El-Sayed M, El-kady M Y . Treatment of oil-water emulsions by adsorption onto activated carbon, bentonite and deposited carbon[J]. Egyptian Petroleum Research Institute, 2011,20(2):9. | | 7 | Pan J, Xu L, Dai J, Li X , et al. Magnetic molecularly imprinted polymers based on attapulgite/Fe3O4 particles for the selective recognition of 2,4-dichlorophenol[J]. Chemical Engineering Journal, 2011,174:68. | | 8 | Zhai R, Tian F, Xue R, Jiao F , et al. Metal ion-immobilized magnetic nanoparticles for global enrichment and identification of phosphopeptides by mass spectrometry[J]. RSC Advances, 2016,6:1670. | | 9 | Song R, Bai B, Puma G L , et al. Biosorption of azo dyes by raspberry-like Fe3O4@yeast magnetic microspheres and their efficient regeneration using heterogeneous fenton-like catalytic processes over an up-flow packed reactor[J]. Reaction Kinetics, Mechanisms and Catalysis, 2015,115:547. | | 10 | Konwar A, Gogoi A, Chowdhury D . Magnetic alginate-Fe3O4 hydrogel fiber capable of ciprofloxacin hydrochloride adsorption/separation in aqueous solution[J]. RSC Advances, 2015,5:81573. | | 11 | Lee H, Dellatore S M, Miller W M , et al. Mussel-inspired surface chemistry for multifunctional coatings[J]. Science, 2007,318(5849):426. | | 12 | Huang S . Mussel-inspired one-step copolymerization to engineer hierarchically structured surface with superhydrophobic properties for removing oil from water[J]. ACS Applied Materials & Interfaces, 2014,6(19):17144. | | 13 | Wang H, Wang E, Liu Z , et al. A novel carbon nanotubes reinforced superhydrophobic and superoleophilic polyurethane sponge for selective oil-water separation through a chemical fabrication[J]. Journal of Materials Chemistry A, 2015,3:266. | | 14 | Likon M, Remskar M, Ducman V et al. Populus seed fibers as a natural source for production of oil super absorbents[J]. Journal of Environmental Management, 2013,114:158. | | 15 | Wang J, Zheng Y, Wang A . Preparation and properties of kapok fiber enhanced oil sorption resins by suspended emulsion polymerization[J]. Journal of Applied Polymer Science, 2013,127:2184. | | 16 | Sun X F, Sun R C, Sun J X . Acetylation of sugarcane bagasse using NBS as a catalyst under mild reaction conditions for the production of oil sorption-active materials[J]. Bioresource Technology, 2004,95:343. | | 17 | Kim B G, Kim S, Lee H , et al. Wisdom from the human eye: A synthetic melanin radical scavenger for improved cycle life of Li-O2 battery[J]. Chemistry of Materials, 2014,26:4757. | | 18 | Zeng A, Chen R, Lin Z , et al. SO2 adsorption property of polydopamine/montmorillonite composites[J]. Chinese Journal of Environmental Engineering, 2015,9(10):4982(in Chinese). | | 19 | 曾安然, 陈汝盼, 林志杰 , 等. 聚多巴胺/蒙脱土复合材料对SO2的吸附性能[J]. 环境工程学报, 2015,9(10):4982. | | 20 | Yang L, Wang Z, Yang L , et al. Coco peat powder as a source of magnetic sorbent for selectiveoil-water separation[J]. Industrial Crops and Products, 2017,101:1. |

|

|

|

|

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

2018, Vol. 32

2018, Vol. 32