| RESEARCH PAPER |

|

|

|

|

|

|

| Study on the Preparation and Properties of Textile-ramie Fiber Reinforced In-situ Anionic Polyamide-6 Composites |

| Guangzhi LIU1,Wei LI1,2,Youqing FEI1

|

1 College of Materials Science and Engineering, Hunan University, Changsha 410082

2 Hunan Province Key Laboratory for Spray Deposition Technology and Application, Hunan University,Changsha 410082 |

|

|

|

|

Abstract In this paper, textile-ramie fiber (RF) reinforced anionic polyamide-6 (APA6) composites were prepared successfully with the heat treated ramie fiber and caprolactam as monomer.The effects of the heat-treatment on the functional groups, the crystallization, the mechanical properties and the fracture morphology of the ramie fiber were studied. Meanwhile, the mechanical properties, thermal stability, as well as interfacial properties of the RF/APA6 composites were also investigated. The results showed that the hydroxyl groups covering on the ramie fiber surface decreased significantly, the crystallinity, the tensile strength and modulus decreased after the 280 ℃ heat-treatment, but no obvious changes in the morphology of the ramie fiber. The interfacial adhesion between the resin and the ramie fiber of the RF/APA6 composites was excellent. Compared with the neat APA6, the tensile strength of the composites increased slightly, while the tensile modulus, flexural property and the thermal stability were increased significantly.

|

|

Published: 25 January 2018

Online: 2018-01-25

|

|

|

|

|

|

|

The evolution of the anionic polymerization results of RF-reinforced APA6 composites differing in heat-treatment temperature of ramie fiber

|

|

|

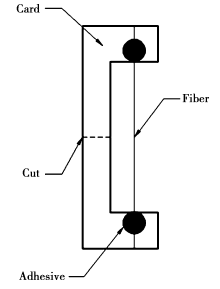

The diagrammatic sketch of the sample card

|

|

|

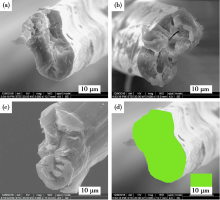

The tensile fracture morphology of ramie fibers: (a)untreated; (b)160 ℃ heat-treated; (c)280 ℃ heat-treated; (d)the processing diagram of Photoshop

|

|

|

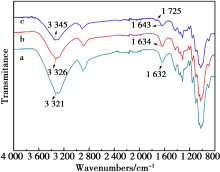

FTIR spectra of ramie fibers: (a)untreated; (b)160 ℃ heat-treated; (c)280 ℃ heat-treated

|

|

|

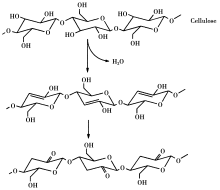

Mechanism of intramolecular dehydration process of cellulose

|

|

|

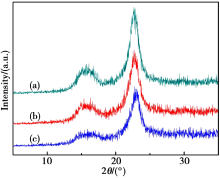

XRD diffractograms for the ramie fiber:(a)untreated; (b)160 ℃ heat-treated;(c)280 ℃ heat-treated

|

| Index | Samples | Max | Min | Average | STDVE | Count | | Tensile strength/MPa | Untreated | 1 384 | 741 | 1 098 | 163 | 15 | | 160 ℃ | 1 098 | 759 | 898 | 105 | 15 | | 280 ℃ | 318 | 158 | 205 | 47 | 15 | | Tensile modulus/GPa | Untreated | 51.5 | 29.4 | 41.6 | 6.3 | 15 | | 160 ℃ | 50.3 | 24.6 | 35.5 | 7.1 | 15 | | 280 ℃ | 29.1 | 15.9 | 23.0 | 3.2 | 15 |

|

|

The mechanical properties of the single ramie fiber after heat treatment at different temperatures

|

|

|

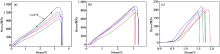

The tensile stress-strain curves of ramie fibers: (a)untreated; (b)160 ℃ heat-treated; (c)280 ℃ heat-treated

|

|

|

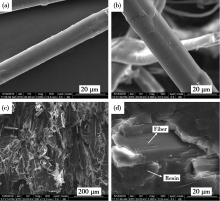

SEM micrographs of (a) untreated ramie fibers, (b) 280 ℃ heat-treated ramie fibers; (c,d) fractured surface morphology of ramie-fiber-reinforced APA6 composites with 280 ℃ heat-treated ramie fibers

|

| Samples | Tensile

strength

MPa | Tensile

modulus

MPa | Flexural

strength

MPa | Flexural

modulus

MPa | | Neat APA6 | 55.7 | 1 633.7 | 63.3 | 1 431.8 | | RF/APA6 | 57.8 | 3 062.1 | 120.6 | 3 578.7 |

|

|

The mechanical properties of the neat APA6 and RF/APA6 composites

|

| Samples | T1%/℃ | T5%/℃ | T10%/℃ | T50%/℃ | | Neat APA6 | 153.1 | 279.7 | 294.5 | 332.2 | | RF/APA6 | 151.7 | 297.5 | 381.1 | 435.6 |

|

|

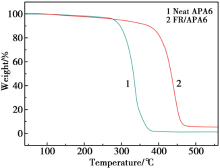

Temperatures corresponding to the weight losses of 1%,5%,10% and 50% during thermogravimetry test of the neat APA6 and RF/APA6 composites

|

|

|

Thermogravimetric curves of the neat APA6 and RF/APA6 composites

|

| 1 | Tan Shouzai, Wang Meigui, Song Yonghong . The modification research of MC nylon[J]. Journal of Guangdong Industry Technical College, 2006,5(2):1(in Chinese). | | 2 | 谭寿再, 王玫瑰, 孙永红 . MC尼龙的改性研究[J]. 广东轻工职业技术学院学报, 2006,5(2):1. | | 3 | Cheng Xiaochun, Yao Cheng . Studies on MC nylon modified with laurolactam[J]. Journal of Nanjing Normal University (Engineering and Technology), 2004,4(4):61(in Chinese). | | 4 | 程晓春, 姚成 . 十二内酰胺改性铸型尼龙的研究[J]. 南京师范大学学报, 2004,4(4):61. | | 5 | Jiang Ying, Yang Guisheng, Wu Yucheng . Recent progress in modification of PA6 via anionic polymerization[J]. Plastics Science and Technology, 2013,41(12):96(in Chinese). | | 6 | 蒋英, 杨桂生, 吴玉程 . 阴离子聚合聚酰胺6改性研究的新进展[J]. 塑料科技, 2013,41(12):96. | | 7 | Hou L, Yang G . Morphology and thermal properties of MC PA6/ABS by in situ polymerization of e-caprolactam[J]. Macromolecular Chemistry and Physics, 2005,206(18):1887. | | 8 | Rusu G, Rusu E . Anionic nylon 6/TiO2 composite materials: Effects of TiO2 filler on the thermal and mechanical behavior of the composites[J]. Polymer Composites, 2012,33(9):1557. | | 9 | Rijswijk K V, Bersee H E N, Beukers A , et al. Optimisation of anionic polyamide-6 for vacuum infusion of thermoplastic compo-sites: Influence of polymerisation temperature on matrix properties[J]. Polymer Testing, 2006,25(3):392. | | 10 | Rijswijk K V, Bersee H E N, Jagerb W F , et al. Optimisation of anionic polyamide-6 for vacuum infusion of thermoplastic compo-sites: Choice of activator and initiator[J]. Composites Part A, 2006,37:949. | | 11 | Lin Jinqing, Huang Hai, Xu Xubo , et al. Synjournal and characte-rization of CF/MC nylon 6 in-situ composites[J]. Journal of Huaqiao University (Natural Science), 2006,27(1):92(in Chinese). | | 12 | 林金清, 黄海, 徐旭波 , 等. 碳纤维/MC尼龙6原位复合材料的制备与表征[J]. 华侨大学学报(自然科学版), 2006,27(1):92. | | 13 | Tian Wenwei, Deng Xiangyun, Zhang Haitao , et al. Preparation of PA6/KF composite using in-situ polymerization[J]. Plastics, 2012,41(5):70(in Chinese). | | 14 | 田文伟, 邓湘云, 张海涛 , 等. 原位聚合法制备PA6/KF复合材料[J]. 塑料, 2012,41(5):70. | | 15 | Yang Yazhou, Tong Jin, Ma Yunhai , et al. Study on modification of jute fibers and mechanical properties of phenolic resin matrix composites reinforced with jute fibers[J]. Journal of Jilin Agricultural University, 2009,31(6):788(in Chinese). | | 16 | 杨亚洲, 佟金, 马云海 , 等. 改性黄麻纤维和酚醛树脂复合材料的力学性能[J]. 吉林农业大学学报, 2009,31(6):788. | | 17 | Liang S, Nouril H, Lafranchel E . Thermo-compression forming of flax fibre-reinforced polyamide-6 composites: Influence of the fibre thermal degradation on mechanical properties[J]. Journal of Mate-rials Science, 2015,50(23):7660. | | 18 | Ga?an P, Garbizu S, Llano-Ponte R , et al. Surface modification of sisal fibers: Effects on the mechanical and thermal properties of their epoxy composites[J]. Polymer Composites, 2005,26(2):121. | | 19 | Zhou Nanting . Interfacial, structure and mechanical properties of ramie fiber reinforced poly(lactic acid) (PLA) composites[D]. Shanghai:Donghua University, 2014. | | 20 | 周楠婷 . 苎麻纤维增强聚乳酸复合材料的界面、结构改进及其力学性能研究[D]. 上海:东华大学, 2014. | | 21 | Li S, Ren J, Yuan H , et al. Influence of ammonium polyphosphate on the flame retardancy and mechanical properties of ramie fiber-reinforced poly(lactic acid) biocomposites[J]. Polymer International, 2010,59(2):242. | | 22 | Segal L, Creely J, Martin A E J , et al. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer[J]. Textile Research Journal, 1959,29(10):786. | | 23 | Shen Hanzhi . Preparation and properties of heat-treated plant fiber/poly(lactic acid) composites[D]. Guangzhou:South China University of Technology, 2011. | | 24 | 沈寒知 . 热处理植物纤维/聚乳酸复合材料的制备与性能研究[D]. 广州:华南理工大学, 2011. | | 25 | Prasad N, Agarwal V K, Sinha S . Banana fiber reinforced low-density polyethylene composites: Effect of chemical treatment and compatibilizer addition[J]. Iranian Polymer Journal, 2016,25(3):229. | | 26 | Jazaeri E, Tsuzuki T . Effect of pyrolysis conditions on the properties of carbonaceous nanofibers[J]. Cellulose, 2013,20(2):707. | | 27 | Wada M, Okano T . Localization of Iαand Iβ phases in algal cellulose revealed by acid treatments[J]. Cellulose, 2001,8(3):183. | | 28 | Ruan Peiying . Experimental study on application of radio frequency and microwave heating into retting of flax straws[D]. Huhhot:Inner Mongolia Agricultural University, 2015. | | 29 | 阮培英 . 射频和微波热处理应用于亚麻原茎脱胶的试验研究[D]. 呼和浩特:内蒙古农业大学, 2015. |

|

|

|

|

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

2018, Vol. 32

2018, Vol. 32