|

|

|

|

|

Published: 25 January 2018

Online: 2018-01-25

|

|

|

|

|

| Sample | Al | Cr | Co | Fe | Ni | Mo | Ti | Si | | AlCrCoFeNiMoSi | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | AlCrCoFeNiMo-

Ti0.25Si0.75 | 1 | 1 | 1 | 1 | 1 | 1 | 0.25 | 0.75 | AlCrCoFeNiMo-

Ti0.5Si0.5 | 1 | 1 | 1 | 1 | 1 | 1 | 0.5 | 0.5 | AlCrCoFeNiMo-

Ti0.75Si0.25 | 1 | 1 | 1 | 1 | 1 | 1 | 0.75 | 0.25 | | AlCrCoFeNiMoTi | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 |

|

|

Composition of high entropy alloys

|

| Lattice

constant

nm | Density

g/cm3 | Cohesive

energy

eV/atom | | AlCrCoFeNiMoSi | 0.279 3 | 8.197 3 | -123.80 | | AlCrCoFeNiMoTi0.25Si0.75 | 0.279 9 | 8.254 1 | -129.77 | | AlCrCoFeNiMoTi0.5Si0.5 | 0.279 9 | 8.361 2 | -139.64 | | AlCrCoFeNiMoTi0.75Si0.25 | 0.280 4 | 8.423 0 | -152.87 | | AlCrCoFeNiMoTi | 0.279 0 | 8.661 1 | -169.98 |

|

|

Lattice constants, density and cohesive energy of high entropy alloys

|

| C11/GPa | C12/GPa | C44/GPa | | AlCrCoFeNiMoSi | 73.32 | 119.30 | 87.20 | | AlCrCoFeNiMoTi0.25Si0.75 | 79.48 | 121.79 | 92.10 | | AlCrCoFeNiMoTi0.5Si0.5 | 96.58 | 125.02 | 103.48 | | AlCrCoFeNiMoTi0.75Si0.25 | 88.20 | 122.80 | 104.27 | | AlCrCoFeNiMoTi | 88.86 | 134.91 | 114.61 |

|

|

Elastic constants Cij of high entropy alloys

|

| E/GPa | G/GPa | B/GPa | G/B | ν | | AlCrCoFeNiMoSi | -74.46 | -25.98 | 103.98 | -0.25 | 0.62 | | AlCrCoFeNiMoTi0.25Si0.75 | -67.91 | -16.94 | 107.69 | -0.16 | 0.61 | | AlCrCoFeNiMoTi0.5Si0.5 | -44.48 | 5.82 | 115.54 | 0.05 | 0.56 | | AlCrCoFeNiMoTi0.75Si0.25 | -54.74 | -0.97 | 111.27 | -0.01 | 0.58 | | AlCrCoFeNiMoTi | -73.82 | -11.42 | 119.56 | -0.10 | 0.60 |

|

|

The Young’s modulus E,shear modulus G,bulk modulus B,G/B and Poisson’s ratio ν of high entropy alloys

|

| AlCrCoFeNiMoTixSiy | x=0,

y=1 | x=0.25,

y=0.75 | x=0.5,

y=0.5 | x=0.75,

y=0.25 | x=1,

y=0 | Average

hardness | | The original sample after melting | 41.5 | 45.5 | 47.0 | 46.4 | 45.6 | 45.2 | | Annealed sample | 50.5 | 52.0 | 48.6 | 52.5 | 51.5 | 51 |

|

|

Hardness of high entropy alloys (HRC)

|

|

|

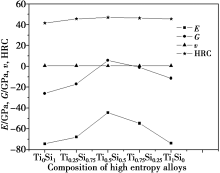

The Young’s modulus E, shear modulus G, Poisson’s ratio ν and HRC of high entropy alloys casting

|

|

|

SEM micrographs of AlCrCoFeNiMoTixSiy high entropy alloys casting: (a)x=0,y=1;(b)x=0.25,y=0.75;(c)x=0.5,y=0.5;(d)x=0.75,y=0.25;(e)x=1,y=0

|

| 1 | Zhou Y J, Zhang Y, Wang Y L , et al. Microstructure characterization of Alx(TiVCrMnFeCoNiCu)100-x high-entropy alloy system with multi-principal elements[J]. Rare Metal Materials and Engineering, 2007,36(12):2136(in Chinese). | | 2 | 周云军, 张勇, 王艳丽 , 等. 多组元Alx(TiVCrMnFeCoNiCu)100-x高熵合金系微观组织研究[J]. 稀有金属材料与工程, 2007,36(12):2136. | | 3 | Li K . Microstructure and hydrogen storage properties of the lightweight and containing magnesium high entropy alloys[D]. Lanzhou: Lanzhou University of Technology, 2013(in Chinese). | | 4 | 李凯 . 轻质及含镁高熵合金的微观组织及储氢性能研究[D]. 兰州:兰州理工大学, 2013. | | 5 | Yang X, Zhang Y, Liaw P K . Microstructure and compressive pro-perties of NbTiVTaAlx high entropy alloys[J]. Procedia Enginee-ring, 2012,36(6):292. | | 6 | Yu Y, Xie F Q, Zhang T B , et al. Microstructure control and corrosion properties of AlCoCrFeNiTi0.5 high-entropy alloy[J]. Rare Metal Materials and Engineering, 2012,41(5):862(in Chinese). | | 7 | 于源, 谢发勤, 张铁邦 , 等. AlCoCrFeNiTi0.5高熵合金的组织控制和腐蚀性能[J]. 稀有金属材料与工程, 2012,41(5):862. | | 8 | Varalakshmi S, Kamaraj M, Murty B S . Synjournal and characterization of nanocrystalline AlFeTiCrZnCu high entropy solid solution by mechanical alloying[J]. Journal of Alloys and Compounds, 2008,460(1-2):253. | | 9 | Wu J M, Lin S J, Yeh J W , et al. Adhesive wear behavior of AlxCoCrCuFeNi high-entropy alloys as a function of aluminum content[J]. Wear, 2006,261(5-6):513. | | 10 | 7 Yang J Y,Zhou Y J,Zhang Y,et al. Research progress of high-entropy alloys with multiprincipal components[J].Chinese Materials Science Technology and Equipment, 2007(6):16(in Chinese). | | 11 | 阳隽觎, 周云军, 张勇 , 等. 多组元高熵合金的研究现状及前景展望[J].中国材料科技与制备, 2007(6):16. | | 12 | Zhang Y, Zuo T T, Tang Z , et al. Microstructures and properties of high-entropy alloys[J]. Progress in Materials Science, 2014,61(8):1. | | 13 | Yang X M . First-principles study on structure and properties of Mg-Al based strengthening phase and solid solution[D]. Taiyuan: North University of China, 2014(in Chinese). | | 14 | 杨晓敏 . Mg-Al基强化相及固溶体结构和性能的第一性原理研究[D]. 太原:中北大学, 2014. | | 15 | Ju S P, Huang H H, Wu T Y , et al. Investigation of the local structural rearrangement of Mg67Zn28Ca5 bulk metallic glasses during tensile deformation:A molecular dynamics study[J]. Computational Materials Science, 2015,96:56. | | 16 | Jung G S, Zhao Q, Buehler M J . Molecular mechanics of polycrystalline graphene with enhanced fracture toughness[J]. Extreme Mechanics Letters, 2015,2(1):52. | | 17 | Hizhnyakov V, Haas M , Shelkan, et al. Theory and MD simulations of intrinsic localized modes and defect formation in solids[J]. Physica Scripta, 2013,89(4):044003. | | 18 | Wang L X, Yao S, Wen B . First-principle studies of AlCoCrCuxFeNi high entropy alloys with different mole fractions of Cu[J]. Materials Review, 2014,28(s2):159(in Chinese). | | 19 | 王兰馨, 姚山, 温斌 . 第一性原理计算Fe元素含量对高熵合金AlCoCrCuFexNi的影响[J]. 材料导报, 2014,28(专辑24):159. | | 20 | Qiu Y, Wang H P, Kong Y , et al. Progress in first-principles calculations and experimental observations of the interface in cemented carbides[J]. Materials Review A: Review Papers, 2016,30(5):136(in Chinese). | | 21 | 邱玥, 王辉平, 孔毅 , 等. 硬质合金界面的实验观测与第一性原理计算研究进展[J]. 材料导报:综述篇, 2016,30(5):136. | | 22 | Jiang Y . First principles computation methods and applications for metal/metal-oxide interfaces[J]. Chinese Journal of Nature, 2015,37(4):261(in Chinese). | | 23 | 江勇 . 金属与金属氧化物界面第一性原理计算研究方法及其应用[J]. 自然杂志, 2015,37(4):261. | | 24 | Wang C Y, Wang Z Q, Meng Q Y . Comparative study of the first-principles and empirical potential simulation of vacancies in silicon[J]. Acta Physica Sinica, 2010,59(5):3370(in Chinese). | | 25 | 王超营, 王振清, 孟庆元 . 空位的第一性原理及经验势函数的对比研究[J]. 物理学报, 2010,59(5):3370. | | 26 | Li Y, Zhang W P, Yang Q . The first principles calculation of cubic boron nitride electronic structure and optical properties[J]. Materials Review, 2011,25(s2):251(in Chinese). | | 27 | 李耀, 张卫平, 杨强 . 立方氮化硼电子结构和光学性质的第一性原理计算[J]. 材料导报, 2011,25(专辑18):251. | | 28 | Han P D, Bai J G, Li H F . First principle investigation on the alloying effect and Mg/Li interface structure[J]. Journal of Taiyuan University of Technology, 2012,43(3):251(in Chinese). | | 29 | 韩培德, 白晋纲, 李洪飞 . Mg-Li合金界面结构及合金化效应的第一性原理研究[J]. 太原理工大学学报, 2012,43(3):251. | | 30 | Nakamura K, Ohnuma T, Ogata T . First-principles study of structure,vacancy formation,and strength of bcc Fe/V4C3 interface[J]. Journal of Materials Science, 2011,46(12):4206. | | 31 | Fang L H, Wang L, Gong J H , et al. First-principles study of bulk and (001) surface of TiC[J]. Transactions of Nonferrous Metals Society of China, 2010,20(5):857. | | 32 | Fang C M, Van Huis M A, Sluiter M H F , et al. Stability,structure and electronic properties of γ-Fe23C6 from first-principles theory[J]. Acta Materialia, 2010,58(8):2968. | | 33 | Fu C L, Wang X, Ye Y Y , et al. Phase stability, bonding mechanism,and elastic constants of Mo5Si3 by first-principles calculation[J]. Intermetallics, 1999,7(2):179. | | 34 | Gao L, Zhou J, Sun Z M , et al. First-principles calculations of the β-Mg7Gd precipitate in Mg-Gd binary alloys[J]. Chinese Science Bulletin, 2011,56(11):1142. | | 35 | 4 Mattesini M, Ahuja R, Johansson B . Cubic Hf3N4 and Zr3N4: A class of hard materials[J]. Physical Review B, 2003,68(18):184108. |

|

|

|

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

2018, Vol. 32

2018, Vol. 32