| RESEARCH PAPER |

|

|

|

|

|

|

| Influence of Density on Mechanical and Thermal Performance of C/C Composite |

| Huizhen XIE1,2,Jiantao SUN1,Xuanyu HE1,Pengfei XUE1,Shuying QIN1

|

1 Xi’an Aerospace Composites Research Institute, Xi’an 710025;

2 National and Local Union Engineering Research Center of High-performance Carbon Fiber Manufacture and Application, Xi’an 710089; |

|

|

|

|

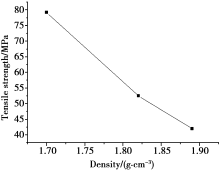

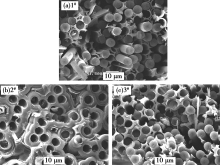

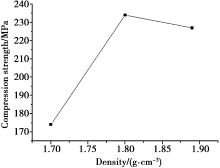

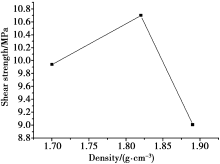

Abstract Three kinds of C/C composites with density of 1.70 g/cm 3, 1.82 g/cm 3 and 1.89 g/cm 3 were prepared. The materials employing needled preform were densified by chemical vapor deposition and pitch impregnation-high pressure carbonization (HPIC) process. The density was controlled by times of HPIC. The results showed that the tensile strength decreased with the increasing density. When the density was low, bonding strength of interface between fiber and matrix was low which could delay the fracture of fiber and increase the tensile strength, the tensile fracture of sample possessed the characteristic of pseudo-plastic fracture. Consisted with the shear strength, the compress strength rose and then fell with the increase of density. With the increasing density, the expansion coefficient increased. Interstices among microcrystals absorbed a little amount of expansion during heating process, therefore, the fall of density was beneficial to the decrease of expansion coefficient of C/C. With the increasing density, the thermal conductivity coefficient increased obviously, and microcrystals enlarged which contribute to the transfer of vibration of crystal lattice and increase of thermal conductivity coefficient. The factor of thermal stress rose and then fell with the increasing density. The C/C with the density of 1.82 g/cm 3 possessed high thermal shock resistance as thermal structure components. In the course of C/C R&D, the density target can be designed according to synthetical demands of mechanical and thermal properties.

|

|

Published: 25 January 2018

Online: 2018-01-25

|

|

|

|

|

| Sample | Bulk density

g·cm-3 | Relative density

% | Porosity

% | Porosity of opening

pore/% | Percentage of opening

pore/% | | 1# | 1.70 | 75.2 | 24.8 | 15.6 | 62.9 | | 2# | 1.82 | 80.5 | 19.5 | 9.9 | 50.8 | | 3# | 1.89 | 83.6 | 16.4 | 4.0 | 24.4 |

|

|

Density and porosity of three kinds of C/C composites

|

|

|

Relationships between tensile strength and density

|

|

|

SEM images of tensile fracture of C/C composites with different density

|

|

|

Relationships between compression strength and density

|

|

|

Relationships between shear strength and density

|

|

|

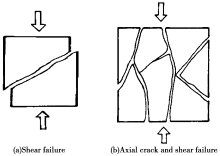

Photo of failure of C/C compression samples

|

|

|

Sketch map of compression failure configuration

|

|

|

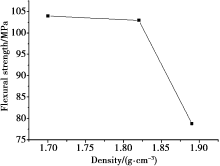

Relationships between flexural strength and density

|

|

|

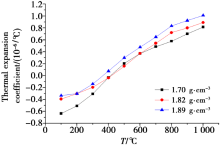

Curve of thermal expansion coefficient

|

|

|

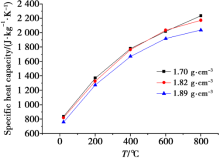

Curve of specific heat capacity

|

|

|

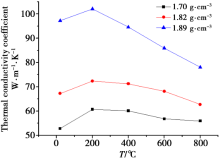

Curve of thermal conductivity coefficient

|

| Sample | Density

g·cm-3 | Tensile

strength

MPa | Thermal conductivity

coefficient

W·m-1·K-1 | Tensile

modulus

GPa | Thermal expansion

coefficient

10-6·K-1 | Thermal stress

factor

kW·m-1 | | 1# | 1.70 | 79.2 | 55.9 | 33.6 | 0.816 | 161.5 | | 2# | 1.82 | 52.5 | 62.7 | 19.1 | 0.891 | 193.4 | | 3# | 1.89 | 42.0 | 78.0 | 17.4 | 1.011 | 186.2 |

|

|

Factor of thermal stress of C/C composites with different density

|

| 1 | Walter Krenkel . Ceramic matrix composites[M]. Weinheim:WILEY-VCH Verlag GmbH & Co.KGaA, 2008: 73. | | 2 | Savage E . Carbon/carbon composites[M]. London: Chapman & Hall, 1993: 15. | | 3 | Chuan X Y, Li H J, Lu J H . Why does cross—extinction property of pyrolytic carbon of C/C composites manufactured by CVI never disappear?[J]. Journal of Northwestern Polytechnical University, 2005,23(5):657(in Chinese). | | 4 | 传秀云, 李贺军, 卢锦花 . 化学气相渗透碳/碳复合材料热解碳光性特征——热解碳十字消光机理探讨[J]. 西北工业大学学报, 2005,23(5):657. | | 5 | Cui Y B, Wang H, Ran X Q , et al. Thermodynamic research on pyrolysis mechanism of carbon matrix precursor ethylbenzene used for carbon/carbon material[J]. Chinese Journal of Organic Chemistry, 2004,24(9):1075(in Chinese). | | 6 | 崔彦斌, 王惠, 冉新权 , 等. 碳/碳复合材料碳源化合物乙苯热裂解机理的热力学研究[J]. 有机化学, 2004,24(9):1075. | | 7 | Shu W B, Qiao S R, Bai S H , et al. Research on rapid electro-pyrolytic densification for C/C composites[J]. Aerospace Materials & Technology, 2000,30(6):32(in Chinese). | | 8 | 舒武炳, 乔生儒, 白世鸿 , 等. 电热解法快速致密C/C复合材料研究[J]. 宇航材料工艺, 2000,30(6):32. | | 9 | Zhang M Y, Huang Q Z, Su Z A , et al. Preparation and microstructure analysis of C/C composites with multi-coupling fields CVI[J]. Journal of Inorganic Materials, 2006,21(6):1373(in Chinese). | | 10 | 张明瑜, 黄启忠, 苏哲安 , 等. 多元耦合场CVI法炭/炭复合材料制备及结构分析[J]. 无机材料学报, 2006,21(6):1373. | | 11 | Lei B L, Yi M Z, Xu H J , et al. Influence of resin-derived carbon content on friction and wear performance of C/C composites[J]. Materials Science and Engineering of Powder Metallurgy, 2011,16(1):115(in Chinese). | | 12 | 雷宝灵, 易茂中, 徐惠娟 , 等. 树脂炭含量对C/C复合材料摩擦磨损性能的影响[J]. 粉末冶金材料科学与工程, 2011,16(1):115. | | 13 | Fan M X, Li H J, Li K Z . Effect of microstructrure of pyrocarbon on the thermal properties of C/C composites[J]. Carbon Techniques, 2007,26(5):10(in Chinese). | | 14 | 范敏霞, 李贺军, 李克智 . 热解碳结构对C/C复合材料热物理性能影响[J]. 炭素技术, 2007,26(5):10. | | 15 | Xie H Z, Fu L K, Sun J T , et al. Influence of carbon fiber distributing on ablative performance of C/C[J]. Materials Science and Enginee-ring of Powder Metallurgy, 2013,18(1):102(in Chinese). | | 16 | 解惠贞, 傅利坤, 孙建涛 , 等. 纤维分布对C/C复合材料烧蚀性能的影响[J]. 粉末冶金材料科学与工程, 2013,18(1):102. | | 17 | Zhang S Y, Li H J, Sun J . Thermal properties and mechanical pro-perties of density gradient carbon/carbon composites[J]. Acta Materiae Compositeae Sinica, 2002,19(5):43(in Chinese). | | 18 | 张守阳, 李贺军, 孙军 . C/C密度梯度材料的热学及力学性能研究[J]. 复合材料学报, 2002,19(5):43. | | 19 | Zhang X H, Li H J, Hao Z B , et al. Influence of needle-punching processing parameters on mechanical properties of C/C composites reinforced by carbon cloth and carbon fiber net[J]. Joarnal of Inorganic Materials, 2007,22(5):963(in Chinese). | | 20 | 张晓虎, 李贺军, 郝志彪 , 等. 针刺工艺参数对炭布网胎增强C/C材料力学性能的影响[J]. 无机材料学报, 2007,22(5):963. | | 21 | 12 乔生儒. 复合材料细观力学性能[M]. 西安: 西北工业大学出版社, 1997: 34. | | 22 | 13 Wong E Y.Solid rocket nozzle design summary[R].New York:AIAA Paper, No. 68-655,1968. |

|

|

|

|

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

2018, Vol. 32

2018, Vol. 32