| RESEARCH PAPER |

|

|

|

|

|

|

| Magnetic Properties and Thermal Stability of Nd-Fe-B Magnets by Recycling Fabrication |

| Toujun ZHOU1,Jiajie LI1,2,Chengjun GUO1,Yunfeng DING1,Jinshui CHEN1

|

1 School of Material Science and Engineering, Jiangxi University of Science and Technology, Ganzhou 341000

2 Institute of Engineering and Research, Jiangxi University of Science and Technology, Ganzhou 341000 |

|

|

|

|

Abstract The sintered Nd-Fe-B magnets were fabricated by short-circuit recycling process. The magnetic properties and thermal stability of the magnets with adding PrNd mixed rare earth were also investigated. The magnetic properties of the magnets with 2% PrNd addition were as follows: the remanence (Br) of 1.31 T, the coercivity (Hcj) of 1 474.86 kA/m, and the maximum energy product [(BH)max] of 353.90 kJ/m 3. Compared to the new qualified magnets, the Br, Hcj and (BH)max values of 95%, 102% and 90%, respectively, were recovered. The magnet thermal stability could be improved by PrNd addition. The temperature coefficient of the coercivity reduced from -0.589 9%/K to -0.556 4%/K in the range of 293—393 K. This is mainly because the addition of mixed rare earth PrNd enhances the demagnetization exchange coupling and the magnetocrystalline anisotropy field of the main phase. Thus the coercivity and thermal stability of the magnets are improved.

|

|

Published: 25 January 2018

Online: 2018-01-25

|

|

|

|

|

Samples

No. | Br

T | Hcj

kA/m | (BH)max

kJ/m3 | Hk/Hcj

% | | 1# | 1.38 | 1 447.01 | 353.90 | 94.5 | | 2# | 1.29 | 1 374.62 | 319.67 | 75.9 | | 3# | 1.32 | 1 436.67 | 325.09 | 63.9 | | 4# | 1.31 | 1 474.86 | 319.99 | 68.5 |

|

|

Magnetic properties of the sintered Nd-Fe-B magnets at room temperature

|

|

|

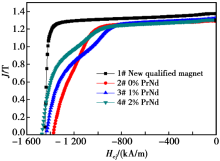

Demagnetization curves of the sintered Nd-Fe-B magnets at room temperature

|

|

|

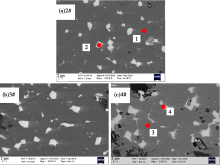

Backscattered electron images of the sintered Nd-Fe-B magnets with various amounts of PrNd

|

| Elements | 1 | 2 | 3 | 4 | | Nd | 21.68 | 68.22 | 21.44 | 72.23 | | Pr | 3.08 | 12.54 | 6.02 | 11.54 | | Fe | 66.85 | 0.98 | 66.57 | 0 | | O | 0 | 9.47 | 0 | 10.70 | | C | 2.12 | 6.15 | 1.71 | 5.54 |

|

|

EDS analysis result (wt%) of 1,2,3 and 4 spots in Fig.2

|

| Samples | Temperature

K | Br

T | Hcj

kA/m | (BH)max

kJ/m3 | | 2# | 293 | 1.29 | 1 374.62 | 319.67 | | | 323 | 1.27 | 1 092.22 | 311.40 | | 353 | 1.24 | 847.21 | 292.13 | | 373 | 1.21 | 698.21 | 276.05 | | 393 | 1.18 | 563.77 | 254.48 | | 4# | 293 | 1.31 | 1 474.86 | 319.99 | | | 323 | 1.26 | 1 186.89 | 301.13 | | 353 | 1.23 | 937.89 | 282.50 | | 373 | 1.20 | 785.95 | 267.77 | | 393 | 1.17 | 654.30 | 249.86 |

|

|

Magnetic properties of the sintered Nd-Fe-B magnets at 293 K,323 K,353 K,373 K and 393 K

|

|

|

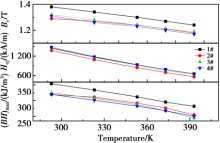

The variation of magnetic properties as a function of temperature of the sintered Nd-Fe-B

|

| 1 | Skomski R, Coey J M D . Magnetic anisotropy—How much is enough for a permanent magnet?[J]. Scripta Materialia, 2016,112:3. | | 2 | Ren C D, Jin W Y, Zhou H B . Key preparation techniques for sintered Nd-Fe-B magnets of high-performance[J]. Chinese Journal of Rare Metals, 2013,37(2):249(in Chinese). | | 3 | 任春德, 金伟洋, 周鸿波 . 高综合性能烧结钕铁硼磁体关键制备技术研究[J]. 稀有金属, 2013,37(2):249 | | 4 | Wu J P, Deng G F, Deng L L . Rare earth recovery from NdFeB magnet scrap[J]. Nonferrous Metals Science and Engineering, 2016,7(1):119(in Chinese). | | 5 | 吴继平, 邓庚凤, 邓亮亮 . 从钕铁硼废料中提取稀土工艺研究[J]. 有色金属科学与工程, 2016,7(1):119. | | 6 | Song N, Zhong X L, Jiang H W , et al. Preparation of Mn-Zn ferrites from NdFeB waste[J]. Materials Review, 2008,22(4):146(in Chinese) | | 7 | 宋宁, 钟晓林, 姜宏伟 , 等. 钕铁硼废渣制备锰锌铁氧体[J]. 材料导报, 2008,22(4):146. | | 8 | Dong S Z, Luo Y, Li W. Development of rare earth permanent magnet in China [C]∥Proceedings of the 23rd International Workshop on Rare Earth and Future Permanent Magnets and their Applications.Annapolis, 2014. | | 9 | Xu T, Li M, Zhang C X . Reclamation of Nd, Dy and Co oxides from NdFeB scrap[J]. Rare Earth, 2004,25(4):2(in Chinese). | | 10 | 许涛, 李敏, 张春新 . 钕铁硼废料中钕、镝及钴的回收[J]. 稀土, 2004,25(4):2. | | 11 | 7 黄平, 罗恩桂 .一种从钕铁硼废料中回收稀土的方法:中国, 101717859A[P]. 2010 -06-02. | | 12 | 8 孟祥林, 桂云栋 . 钕铁硼稀土永磁废料二次真空熔炼再生永磁体的方法:中国, 1127797A[P]. 1996 -07-31. | | 13 | Zakotnik M, Tudor C O . Commercial-scale recycling of NdFeB-type magnets with grain boundary modification yields products with ‘designer properties’ that exceed those of starting materials[J]. Waste Management, 2015,44:48. | | 14 | Zakotnik M, Harris I R, Williams A J . Possible methods of recycling NdFeB-type sintered magnets using the HD/degassing process[J]. Journal of Alloys and Compounds, 2008,450(1-2):525. | | 15 | Zakotnik M, Harris I R, Williams A J . Multiple recycling of NdFeB-type sintered magnets[J]. Journal of Alloys and Compounds, 2009,469(1-2):314. | | 16 | Liu W Q, Li C, Zakotnik M , et al. Recycling of waste Nd-Fe-B sintered magnets by doping with dysprosium hydride nanoparticles[J]. Journal of Rare Earths, 2015,33(8):846. | | 17 | Morimoto K, Kaneko S, Katayama N , et al. Effect of substituting Pr for Nd on magnetic properties of NdFeB HDDR powder[J]. Journal of Alloys and Compounds, 2016,666:118. | | 18 | Chen B C, Liu X G, Chen R J , et al. The mechanism of enhanced magnetic properties of sintered permanent magnets by substitution of Pr for Nd[J]. Journal of Alloys and Compounds, 2012,516:73. | | 19 | Taylor M G, Davies B E, Harris I R. A comparative study of the sintering behaviour of NdFeB and PrFeB for permanent magnet applications[J].Journal of Magnetism and Magnetic Materials , 2002, 242- 245(242):1375. | | 20 | Ahmad I, Davies H A, Kanwal M . Magnetic properties of (Nd,Pr)-Fe-B nanocomposite over quenched and annealed ribbons[J]. Journal of Magnetism and Magnetic Materials, 2012,324(23):3971. | | 21 | Li X T, Yue M, Liu W Q , et al. Large batch recycling of waste NdFeB magnets to manufacture sintered magnets with improved magnetic properties[J]. Journal of Alloys and Compounds, 2015,649:656. | | 22 | Wang X L, Ding K H, Cui S L , et al. Microstructure analysis of magnetic properties of NdFeB permanent magnet[J]. Chinese Rare Earths, 2016,37(1):1(in Chinese). | | 23 | 王晓丽, 丁开鸿, 崔胜利 , 等. 影响NdFeB永磁合金磁性的微观结构分析[J]. 稀土, 2016,37(1):1. | | 24 | Kim J W, Song S Y, Kim Y D . Effect of cyclic sintering process for NdFeB magnet on microstructure and magnetic properties[J]. Journal of Alloys and Compounds, 2012,540:141. |

|

|

|

|

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

2018, Vol. 32

2018, Vol. 32