| RESEARCH PAPER |

|

|

|

|

|

|

| Fe2O3 Photocatalyst Supported on Ultra-fine Fibrous Al2O3 Prepared via Electro- blown Spinning (EBS) with an Application to Organic Dye Degradation |

| Lei LI1,2,Bowen CHENG2,Weimin KANG2,Xiaoguang MA2,Xupin ZHUANG2

|

1 School of Materials Science and Engineering,Tianjin Polytechnic University,Tianjin 300387

2 State Key Laboratory of Separation Membranes and Membrane Processes, Tianjin Polytechnic University, Tianjin 300387 |

|

|

|

|

Abstract Ultra-fine fibrous Al2O3 supported Fe2O3 photocatalyst was prepared by an electro-blown spinning (EBS) method combined with impregnation-calcination process, and characterized by techniques such as SEM,EDS and XRD. Photocatalytic degradation of Reactive Red 195 (RR 195) in aqueous solution was used as a probe reaction to evaluate the product’s photocatalytic activity. The results showed that flexible and ultra-fine fibrous alumina mat, which is appropriate for photocatalyst supporter and has an average diameter of 3.78 μm, can be obtained via electro-blown spinning method. The catalytic experimental results suggested that the optimum photocatalytic performance of the photocatalyst was achieved when the sintering temperature was 500 ℃ and the iron loaded content was 195.5 mg/g. The dye decoloration rate reached 95% within 120 min for the first run with H2O2 and UV light, and it can be maintained 70% after three rounds. Moreover,this photocatalyst still maintained good fabric morphology after reaction and was easier to be separated from dye solution, which could avoid the secondary pollution effectively.

|

|

Published: 25 January 2018

Online: 2018-01-25

|

|

|

|

|

|

|

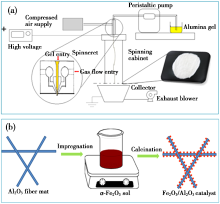

(a)The schematic of the EBS apparatus; (b)schematic diagram for the preparation of Fe2O3/Al2O3 ultra-fine fiber supported photocatalyst

|

|

|

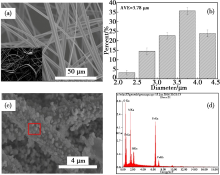

(a) SEM image of EBS alumina fiber mat, and inset was SEM image of solution blowing alumina fiber; (b) diameter distribution of EBS alumina fiber; (c) SEM image of Fe2O3/Al2O3 photocatalyst; (d) EDS image of Fe2O3/Al2O3 photocatalyst

|

|

|

(a)N2 isotherm adsorption-desorption curvers of EBS alumina fiber (inset was BJH pore size distribution) and (b)pore size distribution and average pore size of EBS alumina mat

|

|

|

XRD spectra of (a) EBS alumina fiber and (b) Fe2O3/Al2O3 photocatalyst obtained under different sintering temperature

|

|

|

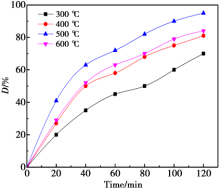

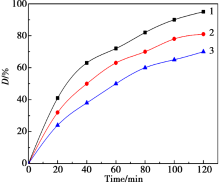

Photocatalytic curves of photocatalyst obtained under different sintering temperature

|

|

|

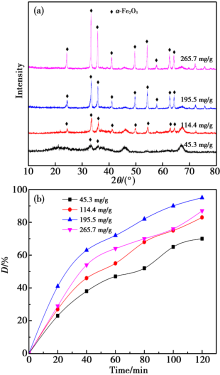

(a) XRD spectra and (b) photocatalytic curves of photocatalyst obtained with different iron loaded contents

|

|

|

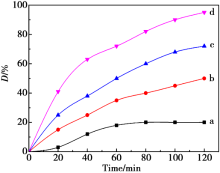

Recycled curves of Fe2O3/Al2O3 ultra-fine fiber supported photocatalyst

|

|

|

The catalytic action of Fe2O3/Al2O3 ultra-fine fiber supported photocatalyst: (a) 0.6 g photocatalyst, dark; (b) 0.6 g photocatalyst, visible light; (c) 0.6 g photocatalyst, UV-light; (d) 0.6 g photocatalyst, 2 mmol/L H2O2, UV-light

|

|

|

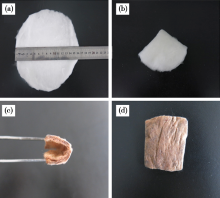

(a)Digital images of EBS alumina fiber mat; (b)the folded EBS alumina fiber mat; (c)digital images of Fe2O3/Al2O3 photocatalyst; (d)digital images of used Fe2O3/Al2O3 photocatalyst

|

| 1 | Jiao Yang, Liu Yang, Zhang Siwen , et al. Visible light driven α-Fe2O3 nanorod photocatalyst[J]. Journal of Nanoscience and Nanotechnology, 2014,14(9):7224. | | 2 | Wei Zhiwei, Wei Xiucheng, Wang Suiyan , et al. Preparation and visible-light photocatalytic activity of α-Fe2O3/γ-Fe2O3, magnetic heterophase photocatalyst[J]. Materials Letters, 2014,118:107. | | 3 | Zhang Yi, Xu Gang, Ou Ping , et al. Preparation and catalytic pro-perty of single crystal multiporous α-Fe2O3 nanorods[J]. Journal of Inorganic Materials, 2008,23(3):459(in Chinese). | | 4 | 张怡, 徐刚, 欧平 , 等. 单晶多孔α-Fe2O3纳米棒的制备及其催化性能[J]. 无机材料学报, 2008,23(3):459. | | 5 | Zhou Weijia, He Wen, Ma Jingyun , et al. Biosynjournal of mesoporous organic-inorganic hybrid Fe2O3 with high photocatalytic activity[J]. Materials Science and Engineering C, 2009,29(6):1893. | | 6 | Chowdhury M, Ntiribinyange M, Nyamayaro K , et al. Photocatalytic activities of ultra-small β-FeOOH and TiO2 heterojunction structure under simulated solar irradiation[J]. International Journal of Photoenergy, 2015,68:133. | | 7 | Jo W K, Shin S H, Chun H H . Application of glass fiber-based N-doped titania under visible-light exposure for photocatalytic degradation of aromatic pollutants[J]. International Journal of Photoenergy, 2014,2014(20):1. | | 8 | Chen Huawei, Ku Young, Kuo Yulin . Effect of Pt/TiO2 characte-ristics on temporal behavior of o-cresol decomposition by visible light-induced photocatalysis[J]. Water Research, 2007,41(10):2069. | | 9 | Liu Chen, Li Youji, Xu Peng , et al. Controlled synjournal of ordered mesoporous TiO2-supported on activated carbon and pore-pore synergistic photocatalytic performance[J]. Materials Chemistry and Physics, 2015,149:69. | | 10 | Torkian L, Amini M M, Amereh E . Sol-gel synjournaled silver doped TiO2 nanoparticles supported on NaX zeolite for photocatalytic applications[J]. Materials Technology, 2013,28(3):111. | | 11 | Venkatesh R, Chakrabarty P K, Siladitya B , et al. Preparation of alumina fibre mats by a sol-gel spinning technique[J]. Ceramics International, 1999,25(6):539. | | 12 | Venkatesh R, Ramanan S R . Influence of processing variables on the microstructure of sol-gel spun alumina fibres[J]. Materals Letters, 2002,55(3):189. | | 13 | Mahapatra A, Mishra B G, Hota G . Synjournal of ultra-fine α-Al2O3 fibers via electrospinning method[J]. Ceramics International, 2011,37(7):2329. | | 14 | Li Zhen, Sheng Jiayi, Wang Yan , et al. Enhanced photocatalytic activity and stability of alumina supported hematite for azo-dye degradation in aerated aqueous suspension[J]. Journal of Hazardous Materials, 2013,254:18. | | 15 | Kim J H, Yoo S J, Kwak D H , et al. Characterization and application of electrospun alumina nanofibers[J]. Nanoscale Research Letters, 2014,9(1):44. | | 16 | Um I C, Fang D, Hsiao B S , et al. Electro-spinning and electro-blowing of hyaluronic acid[J]. Biomacromolecules, 2004,5(4):1428. | | 17 | Sinha-Ray S, Yarin A L, Pourdeyhimi B . The production of 100/400nm inner/outer diameter carbon tubes by solution blowing and carbonization of core-shell nanofibers[J]. Carbon, 2010,48(12):3575. | | 18 | Luo C J, Stoyanov S D, Stride E , et al. Electrospinning versus fibre production methods: From specifics to technological convergence[J]. Chemical Society Reviews, 2012,41(13):4708. | | 19 | Sedaghat A, Taheri-Nassaj E, Naghizadeh R . An alumina mat with a nano microstructure prepared by centrifugal spinning method[J]. Journal of Non-Crystalline Solids, 2006,352(26):2818. | | 20 | Maneeratana V, Sigmund W M . Continuous hollow alumina gel fibers by direct electrospinning of an alkoxide-based precursor[J]. Chemical Engineering Journal, 2008,137(1):137. | | 21 | Li Lei, Kang Weimin, Zhao Yixia , et al. Preparation of flexible ultra-fine Al2O3 fiber mats via the solution blowing method[J]. Ceramics International, 2015,41(1):409. | | 22 | Li Lei, Kang Weimin, Zhuang Xupin , et al. A comparative study of alumina fibers prepared by electro-blown spinning (EBS) and solution blowing spinning (SBS)[J]. Materials Letters, 2015,160:533. | | 23 | Wang Xia, Wang Jianqiang, Cui Zhentao , et al. Facet effect of α-Fe2O3 crystals on photocatalytic performance in the photo-fenton reaction[J]. RSC Advances, 2014,4(65):34387. | | 24 | Li Bing, Dong Yongchun, Zou Chi , et al. Iron(Ⅲ)-alginate fiber complex as a highly effective and stable heterogeneous fenton photocatalyst for mineralization of organic dye[J]. Industrial and Engi-neering Chemistry Research, 2014,53(11):4199. |

|

|

|

|

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

2018, Vol. 32

2018, Vol. 32