| COMPUTATIONAL SIMULATION |

|

|

|

|

|

|

| Multiscale Simulation of Geometric Effect on Onset Plasticity of Nano-scale Asperities |

| Siyuan ZHOU,Jianfeng JIN,Lu WANG,Jingyi CAO,Peijun YANG

|

| Key Laboratory for Anisotropy and Texture of Materials of Education Department, School of Materials Science and Engineering,Northeastern University, Shenyang 110819 |

|

|

|

|

Abstract To understand mechanical behaviors of the asperities on a metal rough surface is helpful for understanding the friction, wear property of materials and designing micro/nano electromechanical devices. In the study, multiscale quasicontinuum (QC) method was used to explore geometric effect on onset plasticity of nano-scale asperities on aluminum and copper thin films during nanoindentation on the (001) surface. The results show that existing asperities significantly reduce the yield stress of thin film, compared with the stress of the flat film. For a rectangular asperity, the aspect ratio (width/height) affects yield stress of both films without much change. For a trapezoidal asperity, the yield stress decreases with the base angle (α), especially when the α is over 54.7°. It is also found that deformation twinning can be formed in the aluminum film under the condition of constraining full dislocation formation at nanoscale.

|

|

Published: 25 January 2018

Online: 2018-01-25

|

|

|

|

|

|

|

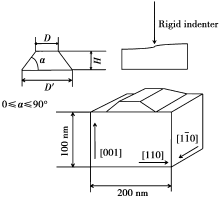

QC model represents a single asperity on the (001) thin film during nanoindentation with a cross-sectional trapezoid shape,where H,α,D and D' is the height, the base angle, top and bottom length, respectively

|

|

|

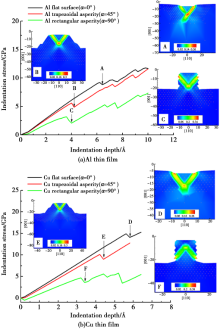

Stress-displacement curves during nanoindentation on a smooth surface and on two asperities (D=20 ?, H=20 ? and α=90°) and (D=20 ?,H=20 ? and α=45°) associated with dislocation morphology of the onset plasticity

|

|

|

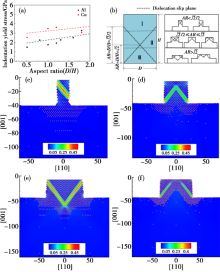

(a)Yield stress and (b)dislocation slip planes with different aspect ratios (AR) of the rectangular patterned lines, and dislocation morphology in the Al film with the asperity of H=40 ?, (c)AR=0.5, (d)AR=1.0, (e)AR=1.8 and (f)dislocation morphology in the Cu film with H=40 ? and AR=1.8

|

|

|

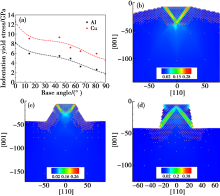

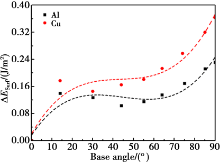

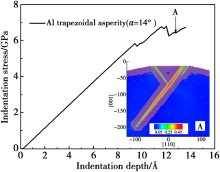

(a)The yield stress of the Al and Cu films containing the asperity at different base angle with the constant D=40 ? and AR=1 and dislocation morphology in the Al film containing the asperity with (b)α=14°, (c)α=55°,and(d)α=81°

|

|

|

The energy (ΔESurf) for evaluating the effect of sidewall surface at different base angles of the asperities with D=40 ?, AR=1.0

|

|

|

(a)Stress-displacement curves of the Al and Cu films with the asperity of AR=1.8 and H=40 ? and (b)dislocation morphology at each force-event event in the curve (a)

|

|

|

Stress-displacement curve on the Al surface with the asperity of D=80 ?,H=40 ?,α=14°, associated with deformation twinning

|

| 1 | Majumdar A A, Bhushan B . Role of fractal geometry in roughness characterization and contact mechanics of surfaces[J]. Journal of Tribology, 1990,112(2):205. | | 2 | Szlufarska L, Chandross M, Carpick R W , et al. Recent advances in single-asperity nanotribology[J]. Journal of Physics D:Applied Phy-sics, 2008,41(12):123001. | | 3 | Gadelmawla E S, Koura M M, Maksoud T M A , et al. Roughness parameters[J]. Journal of Materials Processing Technology, 2002,123(1):133. | | 4 | Zhao Y, Maietta D M, Chang L , et al. An asperity microcontact model incorporating the transition from elastic deformation to fully plastic flow[J]. Journal of Tribology, 2000,122(1):86. | | 5 | Mihailidis A, Bakolas V, Drivakos N , et al. Subsurface stress field of a dry line contact[J]. Wear, 2001,249(7):546. | | 6 | Gao Y F, Bower A F, Kim K S , et al. The behavior of an elastic-perfectly plastic sinusoidal surface under contact loading[J]. Wear, 2006,261(2):145. | | 7 | Sun F, Giessen E V D, Nicola L , et al. Plastic flattening of a sinusoidal metal surface: A discrete dislocation plasticity study[J]. Wear, 2012,296(1-2):672. | | 8 | Liu M, Proudhon H . Finite element analysis of frictionless contact between a sinusoidal asperity and a rigid plane: Elastic and initially plastic deformations[J]. Mechanics of Materials, 2014,77:125. | | 9 | Persson B . Theory of rubber friction and contact mechanics[J]. Journal of Chemical Physics, 2001,115(8):3840. | | 10 | Vorobyev A Y, Makin V S, Guo C , et al. Periodic ordering of random surface nanostructures induced by femtosecond laser pulses on metals[J]. Journal of Applied Physics, 2007,101(3):034903. | | 11 | Rubio G, Agra? N, Vieira S , et al. Atomic-sized metallic contacts: Mechanical properties and electronic transport[J]. Physical Review Letters, 1996,76(13):2302. | | 12 | Shibutani Y, Koyama A . Surface roughness effects on the displacement bursts observed in nanoindentation[J]. Journal of Materials Research, 2004,19(1):183. | | 13 | Nicola L, Giessen E D, Sun F W , et al. Effect of plastic flattening on the shearing response of metal asperities: A dislocation dynamics analysis[J]. Journal of Applied Mechanics, 2015,82(7):071009. | | 14 | Cha P R, Srolovitz D J, Vanderlick T K , et al. Molecular dynamics simulation of single asperity contact[J]. Acta Materialia, 2004,52(13):3983. | | 15 | Miller R E, Tadmor E B . The quasicontinuum method: Overview, applications and current directions[J]. Journal of Computer-Aided Materials Design, 2002,9(3):203. | | 16 | Jin J, Shevlin S A, Guo Z X , et al. Multiscale simulation of onset plasticity during nanoindentation of Al (001) surface[J]. Acta Materialia, 2008,56(16):4358. | | 17 | Li J W, Jiang W G . Predictions of nanohardness and elastic modulus of thin film material with the quasicontinuum method[J]. Acta Metallurgica Sinica, 2007,43(8):851(in Chinese). | | 18 | 黎军顽, 江五贵 . 基于准连续介质法预测薄膜材料纳米硬度和弹性模量[J]. 金属学报, 2007,43(8):851. | | 19 | R?dig T, Sch?necker A, Gerlach G , et al. A survey on piezoelectric ceramics for generator applications[J]. Journal of the American Ceramic Society, 2010,93(4):901. | | 20 | Qi Y, Jafferis N T, Jr L K , et al. Piezoelectric ribbons printed onto rubber for flexible energy conversion[J]. Nano Letters, 2010,10(2):524. | | 21 | Madhu B, Sharath S, Simon R , et al. Nanoscale characterization of energy generation from piezoelectric thin films[J]. Advanced Functional Materials, 2011,21(12):2251. | | 22 | Wang Z L, Song J . Piezoelectric nanogenerators based on zinc oxide nanowire arrays[J]. Science, 2006,312(5771):242. | | 23 | Kim S H, Asay D B, Dugger M T , et al. Nanotribology and MEMS[J]. Nano Today, 2007,2(5):22. | | 24 | Nili H, Cheng G, Venkatesh T A , et al. Correlation between nanomechanical and piezoelectric properties of thin films: An experimental and finite element study[J]. Materials Letters, 2013,90(1):148. | | 25 | 4 Lu Huaibao, Ni Yushan . Effect of surface step on nanoindentation of thin films by multiscale analysis[J]. Thin Solid Films, 2012,520(15):4934. | | 26 | 5 Tadmore E B, Ortiz M, Philips R , et al. Quasicontinuum analysis of defects in solids[J]. Philosophical Magazine A, 1996,73(6):1529. | | 27 | 6 Shenoy V B, Miller R, Tadmor E B , et al. An adaptive finite element approach to atomic-scale mechanics—The quasicontinuum method[J]. Journal of the Mechanics and Physics of Solids, 1999,47(3):611. | | 28 | 7 Foiles S M, Baskes M I, Daw M S , et al. Embedded atom method functions for the FCC metals Cu, Ag, Au, Ni, Pd, Pt, and their alloy[J]. Physical Review B Condensed Matter, 1986,33(12):7983. | | 29 | 8 Zimmerman J A, Gao H, Abraham F F , et al. Generalized stacking fault energies for embedded atom FCC metals[J]. Modelling and Simulation in Materials Science and Engineering, 2000,8(2):103. | | 30 | 9 Horstemeyer M F, Baskes M I, Plimpton S J , et al. Computational nanoscale plasticity simulations using embedded atom potentials[J]. Theoretical and Applied Fracture Mechanics, 2001,37(1):49. | | 31 | 0 Kiely J D, Houston J E . Nanomechanical properties of Au (111), (001), and (110) surfaces[J]. Physical Review B, 1998,57(19):12588. | | 32 | Carrasco E, Gonzalez M A, Rojo J M , et al. Analysis at atomic level of dislocation emission and motion around nanoindentations in gold[J]. Surface Science, 2004,572(2):467. | | 33 | Filleter T, Bennewitz R . Nanometre-scale plasticity of Cu(100)[J]. Nanotechnology, 2007,18(4):044004. | | 34 | 3 Zimmerman J A, Kelchner C L, Klein P A , et al. Surface step effects on nanoindentation[J]. Physical Review Letters, 2001,87(16):165507. | | 35 | 4 Kiely J D, Hwang R Q, Houston J E , et al. Effect of surface steps on the plastic threshold in nanoindentation[J]. Physical Review Letters, 1998,81(20):4424. | | 36 | 5 Tsuru T, Shibutani Y . Anisotropic effects in elastic and incipient plastic deformation under (001), (110), and (111) nanoindentation of Al and Cu[J]. Physical Review B, 2007,75(3):035415. | | 37 | 6 Roundy D, Cohen M L, Krenn C R , et al. Ideal shear strengths of fcc aluminum and copper[J]. Physical Review Letters, 1999,82(13):2713. | | 38 | 37 Rodriguez de la Fuente O, Zimmerman J A, Gonzalez M A , et al. Dislocation emission around nanoindentations on a (001) FCC metal surface studied by scanning tunneling microscopy and atomistic simulation[J]. Physical Review Letters, 2002,88(3):036101. | | 39 | 8 Shan Z W, Mishra R K, Syed Asif S A , et al. Mechanical annealing and source-limited deformation in submicrometre-diameter Ni crystals[J]. Nature Materials, 2008,7(2):115. | | 40 | 39 余永宁. 材料科学基础[M]. 第2版.北京: 高等教育出版社, 2012: 548. | | 41 | 0 Kibey S, Liu J B, Johnson D D , et al. Predicting twinning stress in Fcc metals: Linking twin-energy pathways to twin nucleation[J]. Acta Materialia, 2007,55(20):6843. | | 42 | Guo L J . Nanoimprint lithography: Methods and material requirements[J]. Advanced Materials, 2007,19(4):495. |

|

|

|

|

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

2018, Vol. 32

2018, Vol. 32