| MATERIALS AND SUSTAINABLE DEVELOPMENT: ADVANCED MATERIALS FOR CLEAN ENERGY UTILIZATION |

|

|

|

|

|

|

| Fatigue Crack Initiation Behaviors of Nuclear Power Plant Main Pipe Stainless Steel in Water with High Temperature and High Pressure |

| Huanchun WU1,Fei XUE1,Chengtao LI1,Kewei FANG1,Bin YANG2,Xiping SONG3

|

1 Life Assessment Center, Suzhou Nuclear Power Research Institute, Suzhou 215004

2 Collaborative Innovation Center of Steel Technology, University of Science and Technology Beijing, Beijing 100083

3 State Key Laboratoryfor Advanced Metals and Materials, University of Science and Technology Beijing, Beijing 100083 |

|

|

|

|

Abstract The behaviors of fatigue crack initiation of 316LN and Z3CN20.09M austenite stainless steels (ASSs) were studied by corrosion fatigue test system in high temperature water. The results indicated that the fatigue cracks were mainly initiated at the persistent slip bands (PSBs) on the surface of 316LN ASS. Only a few cracks were initiated at the sub-grain boundaries. While the fatigue cracks were sequentially initiated at PSBs, phase boundaries and corrosion pits of the Z3CN20.09M ASS containing a little part of ferrite, and they were also mainly initiated at PSBs. The crack initiation mechanism at PSBs was analyzed based on composition of oxide film and morphology of cross section of the specimens tested in high temperature water. Moreover, the difference of the crack initiation mechanisms for two kinds of stainless steel was analyzed. Finally, the effect of the ferrite phase on corrosion fatigue property was summarized.

|

|

Published: 10 February 2018

Online: 2018-02-10

|

|

|

|

|

| Element | C | Si | Mn | P | S | Cr | Ni | Mo | N | Fe | | 316LN | 0.02 | 0.75 | 2.00 | 0.045 | 0.030 | 17.01 | 12.53 | 2.48 | 0.14 | Balance | | Z3CN20.09M | 0.024 | 1.09 | 1.11 | 0.023 | 0.039 | 20.16 | 9.06 | 0.26 | 0.033 | Balance |

|

|

Chemical compositions (mass fraction/%) of 316LN and Z3CN20.09M ASSs

|

| Wave shape | Strain amplitude | Strain rate | Temperature | Pressure | Dissolved oxygen | pH | Conductivity | | Triangular wave | ±0.5%,±1.0% | 0.1% ·s-1 | 320/290 ℃ | 11/8 MPa | 10 mg/L | 6.6 | 0.15 μS/cm |

|

|

Test conditions and high temperature water chemistry

|

|

|

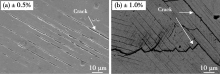

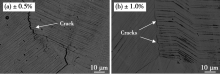

Cracks morphologies at PSBs on the surface of the 316LN ASS at different strain amplitudes in 320 ℃ water

|

|

|

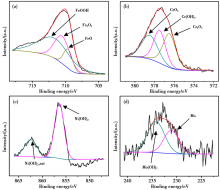

The XPS spectra peaks collected from the oxide films of the 316LN ASS tested in 320 ℃ water:(a) Fe 2p3/2,(b) Cr 2p3/2,(c) Ni 2p3/2,(d) Mo 3d3/2

|

|

|

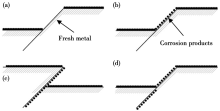

Model of the corrosion fatigue crack initiation process at PSBs

|

|

|

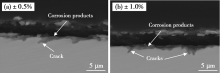

Cross section of the specimens tested at different strain amplitudes of the 316LN ASS tested in 320℃ water

|

|

|

Cracks morphologies at sub-grain boundaries on the surface of the 316LN ASS at different strain amplitudes in 320 ℃ water

|

|

|

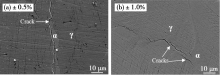

Cracks morphologies at phase boundary on the surface of the Z3CN20.09M ASS at different strain amplitudes in 290℃ water

|

|

|

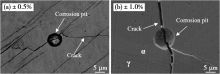

Cracks morphologies at pitting corrosion on the surface of the Z3CN20.09M ASS at different strain amplitudes in 290 ℃ water

|

| 1 | Llanes L, Mateo A, Villechaise P , et al. Effect of testing atmosphere (air/in vacuo) on low cycle fatigue characteristics of a duplex stainless steel[J]. International Journal of Fatigue, 1999,21:S119. | | 2 | Sahu J K, Krupp U, Christ H J . Fatigue crack initiation behavior in embrittled austenitic-ferritic stainless steel[J]. International Journal of Fatigue, 2012,45:8. | | 3 | Mateo A, Gironès A, Keichel J , et al. Cyclic deformation behaviour of superduplex stainless steels[J]. Materials Science and Enginee-ring:A, 2001,314:176. | | 4 | Gironès A, Villechaise P, Mateo A , et al. EBSD studies on the influence of texture on the surface damage mechanisms developed in cyclically loaded aged duplex stainless steels[J].Materials Science and Engineering:A, 2004, 387-389:516. | | 5 | Wu X Q, Xu S, Han E H , et al. Corrosion fatigue of nuclear-grade low alloys stainless steel in high temperature water and its environmental fatigue design model[J]. Acta Metallurgica Sinica, 2011,47(7):790(in Chinese). | | 5 | 吴欣强, 徐松, 韩恩厚 , 等. 核级不锈钢高温水腐蚀疲劳机制及环境疲劳设计模型[J]. 金属学报, 2011,47(7):790. | | 6 | Xu J, Wu X, Han E . The evolution of electrochemical behaviour and oxide film properties of 304 stainless steel in high temperature aqueous environment[J]. Electrochimica Acta, 2012,71:219. | | 7 | Han E H, Wang J Q, Wu X Q , et al. Corrosion mechanisms of stainless steel and nickel base alloys in high temperature high pressure water[J].Acta Metallurgica Sinica,2010(11):1379(in Chinese). | | 7 | 韩恩厚, 王俭秋, 吴欣强 , 等. 核电高温高压水中不锈钢和镍基合金的腐蚀机制[J].金属学报,2010(11):1379. | | 8 | Xu S, Wu X Q, Han E H , et al. Crack initiation mechanisms for low cycle fatigue of type 316Ti stainless steel in high temperature water[J]. Materials Science and Engineering:A, 2008,490:16. | | 9 | Zhao W, Wang Y, Zhang T , et al. Study on the mechanism of high-cycle corrosion fatigue crack initiation in X80 steel[J]. Corrosion Science, 2012,57:99. | | 10 | Roach M D, Wright S I, Lemons J E , et al. An EBSD based comparison of the fatigue crack initiation mechanisms of nickel and nitrogen-stabilized cold-worked austenitic stainless steels[J]. Materials Science and Engineering:A, 2013,586:382. | | 11 | Carstensen J V, Magnin T . Characterisation and quantification of multiple crack growth during low cycle fatigue[J]. International Journal of Fatigue, 2001,23:195. | | 12 | Wu H C, Yang B, Wang S L , et al. Effect of oxidation behavior on the corrosion fatigue crack initiation and propagation of 316LN austenitic stainless steel in high temperature water[J]. Materials Science and Engineering:A, 2015,633:176. | | 13 | Wu H C, Yang B, Shi Y Z , et al. Crack initiation mechanism of Z3CN20.09M duplex stainless steel during corrosion fatigue in water and air at 290 ℃[J]. Journal of Materials Science & Technology, 2015,31:1144. | | 14 | Moulder J F, William F S, Peter E S . Handbook of x-ray and ultraviolet photoelectron spectroscopy[M]. America:Perkin-Elmer Corporation, 1992. | | 15 | Xu S, Wu X Q, Han E H , et al. Study on the fracture of corrosion fatigue crack of the 316Ti stainless steel in simulated nuclear high temperature and high pressure water[J].Journal of Chinese Society for Corrosion and Protection,2010(2):119(in Chinese). | | 15 | 徐松, 吴欣强, 韩恩厚 , 等. 316Ti不锈钢在模拟核电高温高压水中的腐蚀疲劳裂纹断口研究[J].中国腐蚀与防护学报,2010(2):119. | | 16 | Magnin T, Ramade C, Lepinoux J , et al. Low-cycle fatigue damage mechanisms of F.c.c. and B.c.c. polycrystals: Homologous beha-viour?[J]. Materials Science and Engineering:A, 1989,118:41. | | 17 | Strubbia R, Here?ú S, Giertler A , et al. Experimental characterization of short crack nucleation and growth during cycling in lean duplex stainless steels[J]. International Journal of Fatigue, 2014,65:58. | | 18 | Alvarez-Armas I, Knobbe H, Marinelli M C , et al. Experimental characterization of short fatigue crack kinetics in an austeno-ferritic duplex steel[J]. Procedia Engineering, 2011,10:1491. | | 19 | Man J, Vystavěl T, Weidner A , et al. Study of cyclic strain localization and fatigue crack initiation using FIB technique[J]. International Journal of Fatigue, 2012,39:44. | | 20 | Yi Y, Lee B, Kim S , et al. Corrosion and corrosion fatigue beha-viors of 9Cr steel in a supercritical water condition[J]. Materials Science and Engineering:A, 2006,429:161. | | 21 | Pardo A, Merino M C, Coy A E , et al. Pitting corrosion behaviour of austenitic stainless steels - combining effects of Mn and Mo additions[J]. Corrosion Science, 2008,50:1796. | | 22 | Olsson C A . The influence of nitrogen and molybdenum on passive films formed on the austenoferritic stainless steel 2205 studied by AES and XPS[J]. Corrosion Science, 1995,37:467. | | 23 | Marinelli M C, Krupp U, Kübbeler M , et al. The effect of the embrittlement on the fatigue limit and crack propagation in a duplex stainless steel during high cycle fatigue[J]. Engineering Fracture Mechanics, 2013,110:421. | | 24 | Alvarez-Armas I, Krupp U, Balbi M , et al. Growth of short cracks during low and high cycle fatigue in a duplex stainless steel[J]. International Journal of Fatigue, 2012,41(8):95. |

|

|

|

|

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

2018, Vol. 32

2018, Vol. 32