| RESEARCH PAPER |

|

|

|

|

|

|

| Preparation and Characterization of Feather Keratin/PVA Composite Nanofibrous Membranes by Electrospinning |

| Ming HE1,Yao DOU1,Man CHEN2,Guoqiang YIN2,Yingde CUI1,3,Xunjun CHEN2

|

1 School of Materials Science and Engineering, Northwestern Polytechnical University,Xi’an 710072;

2 College of Chemistry and Chemical Engineering,Zhongkai University of Agriculture and Engineering, Guangzhou 510225

3 Guangzhou Vocational College of Science and Technology,Guangzhou 510550 |

|

|

|

|

Abstract Feather keratin (FK)/PVA composite nanofibrous membranes were prepared through an electrospinning process, using water as solvent. The interaction and compatibility between FK and PVA, as well as the effect of incorporating FK on the morphology, crystallinity, thermal stability and hydrophilicity of the composite nanofibrous membranes were evaluated. At a total polymer concentration of 14%, the prepared nanofibers were smooth, bead-free and the average diameter was in the range of 250—320 nm. The more FK was added, the lower fiber diameter was obtained. The favorable compatibility and strong interactions between FK and PVA were confirmed by FTIR analysis. XRD analysis indicated that the arrangement of PVA chain in the composite nanofibrous membranes was disturbed by the incorporation of FK, resulting the decrease of crystallinity. According to TG and contact angle analysis, the thermal stability and hydrophilicity of the composite nanofibers were both enhanced by increasing the FK content.

|

|

Published: 25 January 2018

Online: 2018-01-25

|

|

|

|

|

FK/PVA

ratio | Average diameters of nanofibers/nm | | 14% | 12% | 10% | | 0/10 | 316±43 | 221±31 | 197±34 | | 1/9 | 307±53 | 163±39 | 141±28 | | 2/8 | 260±48 | 137±33 | 140±24 | | 3/7 | 252±49 | 149±48 | 142±21 | | 4/6 | 256±44 | 159±45 | 91±36 |

|

|

Average diameters of FK/PVA nanofibers

|

|

|

SEM images of FK/PVA nanofibers

|

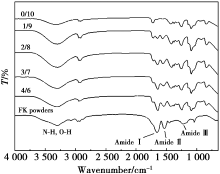

| Samples | Wavenumber/cm-1 | Stretching

vibration of

N-H and O-H | Amide

Ⅰ | Amide

Ⅱ | Amide

Ⅲ | | 0/10 | 3 320 | — | — | — | | 1/9 | 3 298 | 1 647 | 1 565 | 1 255 | | 2/8 | 3 295 | 1 645 | 1 558 | 1 253 | | 3/7 | 3 296 | 1 643 | 1 545 | 1 246 | | 4/6 | 3 297 | 1 640 | 1 545 | 1 244 | | FK powders | 3 281 | 1 655 | 1 535 | 1 226 |

|

|

Infrared characteristic peak of FK/PVA composite nanofibrous membranes and FK powders

|

|

|

FTIR spectra of FK/PVA composite nanofibrous membranes and FK powders

|

|

|

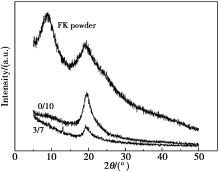

XRD patterns of FK/PVA composite nanofibrous membranes and FK powders

|

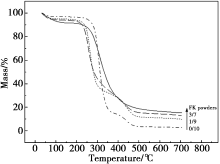

| Samples | Mass loss/% | | 200 ℃ | 350 ℃ | 500 ℃ | 700 ℃ | | 0/10 | 3.6 | 81.1 | 96.2 | 97.2 | | 1/9 | 6.1 | 67.6 | 88.0 | 90.0 | | 3/7 | 7.2 | 65.0 | 84.4 | 87.1 | | FK powders | 8.9 | 58.5 | 81.2 | 84.6 |

|

|

TG analysis of FK/PVA composite nanofibrous membranes and FK powders

|

|

|

TG curves of FK/PVA composite nanofibrous membranes and FK powders

|

|

|

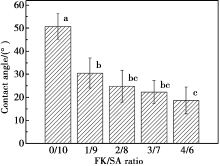

Contact angle of FK/PVA composite nanofibrous membranes Note:Analyzed by Duncan method, different lowercase letters indicate significant differences (p<0.05)

|

| 1 | Agarwal S, Greiner A, Wendorff J H . Electrospinning of manmade and biopolymer nanofibers-progress in techniques,materials,and applications[J]. Advanced Functional Materials, 2010,19(19):2863. | | 2 | Agarwal S, Wendorff J H, Greiner A . Progress in the field of electrospinning for tissue engineering applications[J]. Advanced Materials, 2009,21(32-33):3343. | | 3 | Yen K C, Chen C Y, Huang J Y , et al. Fabrication of keratin/fibroin membranes by electrospinning for vascular tissue engineering[J]. Journal of Materials Chemistry B, 2016,4(2):237. | | 4 | Liu Y, Yu X, Li J , et al. Fabrication and properties of high-content keratin/poly (ethylene oxide) blend nanofibers using two-step cross-linking process[J]. Journal of Nanomaterials, 2015,2015(10):1. | | 5 | Varesano A, Vineis C, Tonetti C , et al. Chemical and physical modifications of electrospun keratin nanofibers induced by heating treatments[J]. Journal of Applied Polymer Science, 2014,131(15):40532. | | 6 | Zoccola M, Aluigi A, Vineis C , et al. Study on cast membranes and electrospun nanofibers made from keratin/fibroin blends[J]. Biomacromolecules, 2008,9(10):2819. | | 7 | Fan J, Lei T D, Li J , et al. High protein content keratin/poly (ethy-lene oxide) nanofibers crosslinked in oxygen atmosphere and its cell culture[J]. Materials and Design, 2016,104:60. | | 8 | Cho D, Nnadi O, Netravali A , et al. Electrospun hybrid soy protein/PVA fibers[J]. Macromolecular Materials and Engineering, 2010,295(8):763. | | 9 | Zhang M, Liu Y J, Yi H L , et al. Electrospun zein/PVA fibrous mats as three-dimensional surface for embryonic stem cell culture[J]. Journal of the Textile Institute, 2014,105(3):246. | | 10 | Li S, Yang X H . Fabrication and characterization of electrospun wool keratin/poly(vinyl alcohol) blend nanofibers[J]. Advances in Materials Science and Engineering, 2014,2014(3):1. | | 11 | Choi J, Panthi G, Liu Y , et al. Keratin/poly (vinyl alcohol) blended nanofibers with high optical transmittance[J]. Polymer, 2015,58(1):146. | | 12 | Song N B, Lee J H, Mijan M A , et al. Development of a chicken feather protein film containing clove oil and its application in smoked salmon packaging[J]. LWT-Food Science and Technology, 2014,57(2):453. | | 13 | Xu X Z, Jiang L, Zhou Z P , et al. Preparation and properties of electrospun soy protein isolate/polyethylene oxide nanofiber membranes[J]. ACS Applied Materials and Interfaces, 2012,4(8):4331. | | 14 | Edwards A, Jarvis D, Hopkins T , et al. Poly(caprolactone)/keratin-based composite nanofibers for biomedical applications[J]. Journal of Biomedical Materials Research Part B-Applied Biomaterials, 2015,103(1):21. | | 15 | Wang H Y, Yin G Q, Feng G Z , et al. Preparation,structure and properties of blend films of feather keratin and sodium carboxy methyl cellulose[J]. Materials Review B:Research Papers, 2014,28(8):67(in Chinese). | | 16 | 王海洋, 尹国强, 冯光炷 , 等. 羽毛角蛋白/CMC复合膜的制备及结构和性能[J]. 材料导报:研究篇, 2014,28(8):67. | | 17 | Islam M S, Karim M R . Fabrication and characterization of poly(vinyl alcohol)/alginate blend nanofibers by electrospinning method[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2010,366(1-3):135. |

|

|

|

|

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

渝公网安备50019002502923号 © Editorial Office of Materials Reports.

2018, Vol. 32

2018, Vol. 32